A long engagement – railways, data and the information age

Article DOI: https://dx.doi.org/10.15180/211603

Abstract

The history of the use of computer and data driven technologies by the railways is largely unknown and is very much overshadowed by a deep fascination with the steam railway. However, it was a willingness to embrace and develop these technologies that laid the foundations for the railway that we have today. This paper aims to show the history of the railway’s ‘long engagement’ with these forms of communication and control technologies. This history forms the background to the increasing adoption of internet-based technology on today’s railway, and thus provides a thread connecting the past, present and future of the rail system.

A central argument here is that railway management of necessity focuses on control to ensure the safe operation and efficient running of trains and the management of a large and scattered workforce.[1] Control of revenue and costs, including wages and pensions,[2] as well as control of trains on heavily used lines, generated the need for control of data from an early stage. Consequently, UK railways were pioneer adopters of a succession of control technologies including the electric telegraph, ‘Hollerith’ tabulating machines and digital computers.

Keywords

Aspinall, BTM, Edmondson, frequency division multiplexing, Hollerith, IBM, ICL, ICT, Phillpotts, Porter, punch cards, route relay interlocking, semi-automatic ground environment, solid state interlocking, St Johnston, Stanier, Tattersall, Total Operations Processing System, Wickens

Introduction

https://dx.doi.org/10.15180/

The steam locomotive is the persistent image of Britain’s railway history. While Britain may have been slow to use electricity to power its railways, behind the scenes it was an early adopter of electrically powered machines in a wide range of areas, from design and accountancy to safety and control. The electric telegraph, electric fail-safe devices, punched card tabulating machines, digital computers and centralised command and control systems using telecommunications technology were all adopted by the railways at an early stage in their development. This article aims to show that the railway’s early use of electric technology meant it was in close alignment with the emergence of computer technology and its forebears, a development history that is arguably more important to the history of the railways today than anything that the ‘steam age’ produced. This history is little known, and suffers from a sort of ‘silo’ mentality where those who know about the history of railways know little about the history of computers and telecommunications, and vice versa, yet there is a large range of literature and good archive sources that show that these two technologies have a long history of interconnection.

Hollerith machines

https://dx.doi.org/10.15180/211603/002In 1908 the ‘Divisional Locomotive Superintendent’ at the Great Western Railway’s Swindon locomotive works, William Stanier, visited Horwich, locomotive works of the Lancashire and Yorkshire Railway (L&Y). Stanier would go on to have a stellar career in steam locomotive design. Designs credited to him include express locomotives like the ‘Princess Coronation’ class of which Duchess of Hamilton is now a star exhibit at the National Railway Museum.[3] In 1908 his decision to visit the L&Y was no doubt influenced by their reputation for innovation and for very fast running,[4] something that had led his contemporary (and sometimes rival) Nigel Gresley[5] to be an apprentice there ten years before. Stanier’s visit to Horwich works might be expected for someone pursuing a career in locomotive design, but he also visited the main offices of the L&Y at Hunts Bank, Manchester. The innovation that he went to see there was the first successful application of ‘Hollerith’ machines to a major UK business.[6] Control of income and expenditure, wages and pensions, and inventory (particularly rolling stock and renewals) was vitally important, hence it is perhaps no surprise that the railways were early adopters of the Hollerith system and that an ambitious young engineer like William Stanier would want to see this ‘US’ innovation in operation.

The ‘Hollerith’ was an electromechanical tabulating machine first used to process the data from the 1890 US Census (Agar, 2003, p 147). The machines read cardboard punched cards – the dominant form of data processing from 1890 until commercial electronic computers arrived in the 1950s. Designer Herman Hollerith was a former instructor in mechanical engineering at Massachusetts Institute of Technology (later very important to the development of the computer age) and had won a competition to produce a machine that could help process the US census returns. Hollerith claimed to have got the idea for using punched cards for storage of data from seeing railway tickets being punched. (Although punched cards as a system for storing data, in the case of pattern design, had been used by the textile industry since 1804 when the first ‘Jacquard loom’ was invented)[7] (Bradbury, 1912). In 1895 the New York Central Railroad had become the first business to use Hollerith machines, using them to process nearly four million waybills per year.[8] The Pennsylvania Railroad adopted the system in 1903 (Cortada, 2000, p 50).

In the UK the ‘Edmondson’ card ticket system (where the use of the ticket is noted by it being punched) was also a means of controlling data, as it was designed for auditing the sale of tickets. The dismissal of the poet Branwell Bronte from his job at Luddendenfoot station on the Manchester and Leeds railway in 1842 for not spotting ‘financial irregularities’ in the ticket accounts[9] is an early example of how the system was as important for managing staff efficiency (or otherwise) as it was for ensuring passengers had paid their fare.

The promotion of the Hollerith system in the UK started in 1904 when the former head of the US Census, Robert P Porter, a British born journalist, established The Tabulator Limited for the sale of Hollerith machines. Their first general manager was the former secretary of the British Westinghouse company Ralegh Philpotts whose work had led him into close contact with the railway industry (Agar, 2003, p 148). In 1903 British Westinghouse had completed the conversion of the Mersey Railway from steam power to electric traction, the first line in the world to make this switch. The following year the Lancashire and Yorkshire Railway opened Britain’s first ‘overground’ electrified railway of any distance between Liverpool and Southport under their general manager, John Aspinall, a regular visitor to the US.[10]

Aspinall took close notice of developments in the US throughout his working life, as well as encouraging his staff to do so (Bulleid, 1967, p 14). It is perhaps no surprise, then, that The Tabulator Limited’s first successful sale to a major UK business was to the Lancashire and Yorkshire Railway company in 1905. In 1907, J Richardson Bennett wrote in the Great Western Railway Magazine[11] that ‘the system of railway accounts, as at present constructed, does not lend itself to any great improvement as far as labour saving devices are concerned’;[12] by then the L&Y was already proving him wrong.

In 1910 at a joint meeting of the Institute of Mechanical Engineers and the American Society of Mechanical Engineers, Aspinall explained that they had ‘adopted the American Hollerith tabulating machines using punched cards for compiling the records and statistics from the 3000 odd driver’s returns put in every day’.[13] By 1913 the L&Y knew that average passenger working earned £1,825 per locomotive, with freight earning £2,290 (Wray, 2004, p 18). Other statistics from 1913 show cost per mile of an engine was £1.99, with cost in wages per engine mile £3.03 – similar to the cost of coal per engine mile of £3.32 (Wray, 2004, p 19). These ‘returns’ allowed the L&Y to understand the actual costs of running a train and make business decisions accordingly.[14] By the time of Aspinall’s speech in 1910 the Great Northern Railway (by then home to locomotive engineer Nigel Gresley)[15] already had a Hollerith machine installation at Doncaster.[16] The Great Western Railway would follow this by 1913[17] and the London General Omnibus Company by 1918 (itself owned by the Underground Electric Railways Company of London – a precursor to London Transport).[18]

In 1907 The Tabulator Limited became the British Tabulating Machine Company (BTM) whilst in 1924, the parent company in the USA, The Tabulating Machine Company became International Business Machines (IBM). By 1928 IBM was employed by Ferrovie dello Stato (Italian State Railways) to automate its administrative process for the organisation of spare parts and the scheduling and allocation of trains.[19] By then ‘nearly all of the railroads in the United States were using Hollerith tabulating machines to manage schedules, inventory and freight’[20] and the technology was in widespread use in Britain, as evidenced by surviving figures on the use of Hollerith cards during the First World War, when the rail system was in peak use. From July 1916 to December 1919, BTM sold 153 million Hollerith cards in the UK, and of this total, eight railway companies used over 22.4 million cards, an average of 7.4 million a year. The largest railway user in this period was the London and North Western Railway, which used over ten million cards (Agar, 2003, p 160). In an unpublished history of the British Tabulating Machine Company Ltd the (anonymous) author wrote ‘If there was one lesson more than another which the 1914–18 war taught it was the use of figures as a means of control’.[21] However, it was in the Second World War that BTM arguably had the most impact when its chief engineer Harold ‘Doc’ Keen (1894–1973) turned Alan Turing’s ideas for a code breaking machine into a working reality – the ‘Bombe’.[22][23] BTM would eventually merge with rivals Powers Samas in 1959, to become International Computers and Tabulators, which for a time was Britain’s answer to the mighty IBM.

The First World War, which ‘taught the use of figures as a means of control’, drove technical innovation in other ways. In particular, the emergence of a hugely improved internal combustion engine would eventually see the steam locomotive replaced as a prime mover on Britain’s railways. Another consequence of the rapid development of engine technology was more robust and reliable road vehicles able to compete with the railways for moving goods and people. This, coupled with an improving road network (especially after investment into the ‘Trunk Roads’, which were government controlled from 1936) meant the inter-war years were a difficult period for Britain’s railways.

In 1942 Gilbert Walker’s report ‘Road and Rail: An Enquiry into the economics of Competition and State Control’ estimated that in 1924 road transport conveyed 13,600 tons of merchandise which would otherwise have gone by rail; by 1935 this total had grown by 50,000 tons’ (Barker and Gerhold, 1993, p 65). As traffic declined the need to keep a tight control over accounts became even more crucial.

The First World War had also forced co-operation on the railways, and post war the government engineered the ‘grouping’ which saw innovative railways like the L&Y lumped in with the less forward looking companies such as the Midland Railway. Both were now part of the London Midland and Scottish, the largest joint stock company in the world, led by the statistician Sir Josiah Stamp. On the east side of the country the Great Northern Railway found itself in amalgamation with companies that had always struggled financially (for example, the North British) as part of the London and North Eastern Railway, whilst the Great Western Railway sailed on much as it had done, and the Southern Railway pulled together railway companies whose mileage stretched from Padstow to Margate. In 1931 William Stanier was headhunted from the GWR to the LMS as their ‘Chief Mechanical Engineer’ to sort out intense internal rivalries and design a new fleet of steam locomotives. The latter would owe much to GWR practice and last until the end of steam power in the UK.[24]

Signalling

https://dx.doi.org/10.15180/211603/003Hollerith type punch card data processors had by this time become embedded as part of the railway accounting systems, though this was not the only means by which electronic control was seeping into a railway still powered by steam. The inter-war rivalry between the ‘Big Four’ (as the railway companies were known) may have produced speed records and publicity stunts like the LNER’s (summer only) non-stop ‘Flying Scotsman’ service (which started in 1928),[25] but signalling, like good accounting, was also vital to the railway’s success and it had developed well beyond the fixed posts and signal arms of the ‘traditional’ railway. Railway signalling systems had been developing uses of electricity since the time of the Cooke and Wheatstone telegraph in 1837 – ‘the first practical use of electricity’.[26] The use of electricity eventually led to three key developments: the block instrument (which was derived from the telegraph and used to ensure only one train was in one ‘block’ of track at any one time); the track circuit (a low voltage form of train detection);[27] and the relay (a simple, robust switch that ensured the correct operation of railway signals). All three meant that some Signal and Telegraph (traditionally known as S&T) staff were in the vanguard of the developing world of electronics, even if all most people saw was a railway dominated by steam traction into the 1960s.

All fail-safe signalling is essentially binary – proceed/don’t proceed – and as early as 1840 a single needle telegraph was in use to control trains on the London and Blackwall railway (for which a 440-yard ‘galvanic rope’ was made, an object better known today as an electric cable – the first in the world).[28]

By 1844 Cooke had laid a telegraph wire alongside the London and South Western Railway between London and Southampton.[29] In February 1845 the Queen’s Speech for the opening of Parliament was transmitted from Nine Elms in London to Portsmouth, at 88 miles the longest circuit then possible in England. The telegraph would help to develop the ‘block instrument’, a communication device at the heart of ‘absolute block’ train control – a system to ensure only one train is on one ‘block’ of track at any one time.[30]

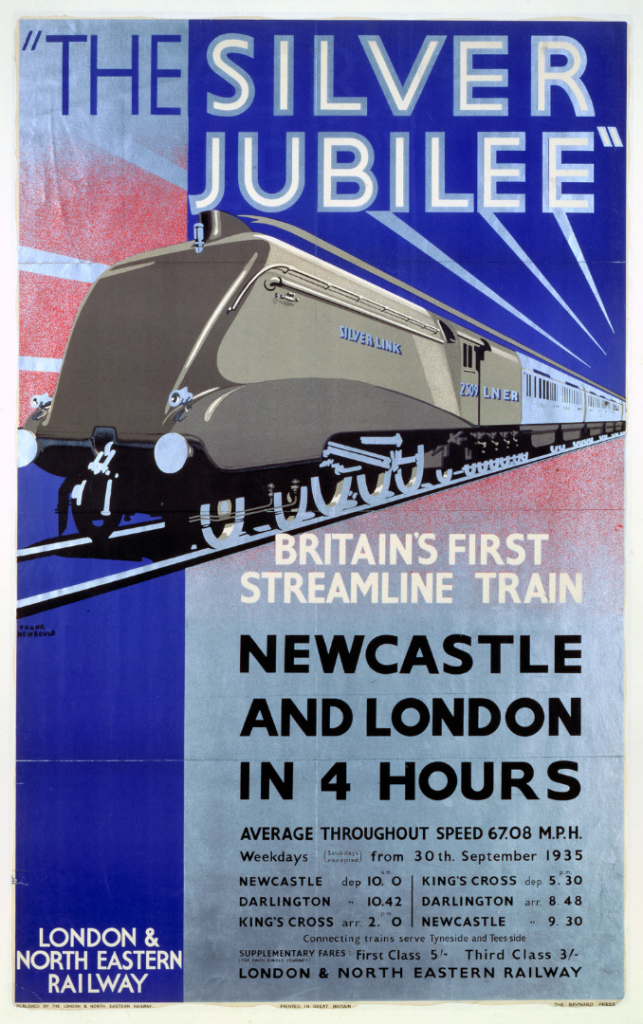

Large infrastructure upgrades were (and are) expensive,[31] particularly on a complex 24/7 network, but doing nothing was also not an option given the pressure of rising costs, in particular wages. The inter-war period on UK railways is defined in the popular imagination by express trains hauled by large steam locomotives, trains like the LMS ‘Royal Scot’, GWR ‘Cornish Riviera Express’, SR ‘Atlantic Coast Express’ or LNER ‘Flying Scotsman’. However, it was during this period that signalling and control innovation really started to emerge, the key development being the Thirsk ‘route relay, route setting’ signal box which opened in 1933. This was part of the modernisation of a key part of the East Coast Main Line (which had been considered for electrification ten years before). At Thirsk signal box (the first of this new system to come into use) ‘in one particular case the moving of a single switch on the panel sets a route right across the yard and the main lines, involving the movement of 14 switches and a signal and is completed in six seconds’.[32] The overall signalling scheme was the brainchild of LNER signal engineer A E Tattersall and opened between York and Northallerton in 1939 (on the day war was declared). This had route setting with visual display in lights, and continuous track circuits covering 25 miles of multiple track main line, as well as route relay interlocking. ‘In Route Relay Interlocking (popularly known as RRI), the Control Rules are implemented through Boolean logic using electromechanical relays.’[33] Boolean logic would of course later be better known as a key part of computer science and lies at the heart of how computer programming is done.

In 1951 (delayed by the Second World War) the largest ‘route relay interlocking’ signal box in the world opened at York, which dealt with ‘827 separate routes’[34] (see Figure 6). By this time railway signal engineers had well over 100 years of experience of working with electricity and were well versed in all aspects of electronics and control systems.[35] Their work paralleled that of the emerging computer world and would eventually lead to practical applications of computer systems on the rail network such as the first computer-based ‘train describer’ installed at Leeds signal box in 1967. This machine, developed by Elliott computers, could pass information on trains in a signalled area automatically, ensuring a smooth flow of trains into and out of the Leeds area. It came into use just as the last steam powered trains worked through the area. Eventually relays themselves would be replaced by ‘Solid State Interlocking’ (SSI),[36] a form of processor-based interlocking, with the first installation going live at Leamington in 1985. SSI led the way to signal boxes controlling large areas of track.

Online, real time, nationwide control of freight

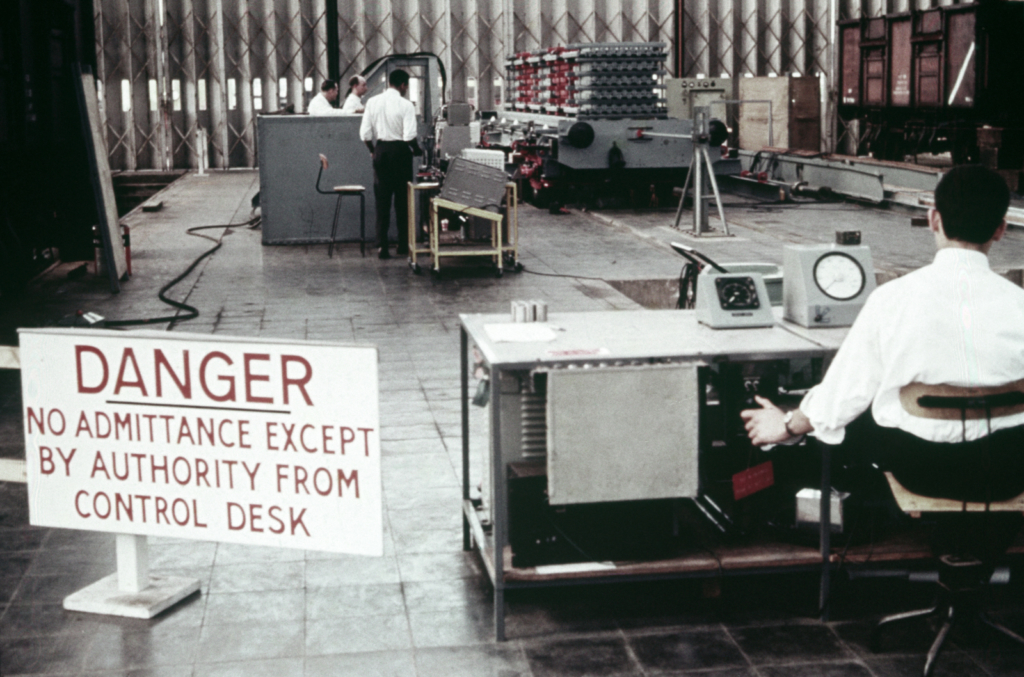

https://dx.doi.org/10.15180/211603/004The railways had been built principally to move freight, and as the motorway age developed so did the need to speed up freight trains, which were still for the most part slow, and steam hauled. New diesels were coming in, capable of travelling long distances without stopping, and of sustaining high speeds for long distances. However, Britain’s freight train vehicles were based on a Victorian approach to wheelset design and suspension, and derailments became commonplace. Here again the railways turned to the potential of the computer. Research into understanding why wagons derailed was one of the aspects of the railway world given to the newly formed British Railways Research Department (BR RD, later the Railway Technical Centre) to tackle. (One positive of railway nationalisation had been to bring long-standing railway industry research units into one organisation, based at Derby.) BR RD had by 1958 (Gilchrist, 2006, p 13) acquired an Elliott 402F computer[37] for their mathematician.[38] Tasked with looking into all the aspects of wagonload freight including speeding up the service, BR RD’s work soon included ‘computer simulation of wagon passage through automated yards’ (Gilchrist, 2006, p 11).

However, it was in research into how to speed up freight trains that BR RD was to have a lasting influenced worldwide. Recruitment of Dr Alan Wickens in 1962 from the aerospace industry (from AVRO) aided by the computing power now at the disposal of what had become BR Research, Derby, swiftly led to a fundamental understanding of the wheel/rail interface. This aspect of railway research was shared internationally and enabled the right approach to rail wheels, vehicle suspension and track to ensure that railways could accelerate services safely, worldwide; it remains a cornerstone of safe operation of trains at speed today.

Around the time Wickens was working on the fundamentals, experiments were already underway to improve control of train movements. In late 1962 the Railway Magazine reported a trial of barcodes on wagons as a way of controlling wagon movement (see Figure 8) in a joint project between Salford Electrical Instruments and BR RD. (The experiment worked but was thought too costly to implement; it predated the use of barcodes on products in supermarkets.) This anticipated using an ICT 1301 Computer of ‘a type which is suited to railway wagon control’.[39] In the same year, in a joint project with Leeds University Computer Laboratory, Devon’s Road Locomotive Depot at Bow in East London became the first in the country to have locomotive scheduling by computer.[40]

The inter-weaving between the railway and the developing computer world would also start to show itself in design terms. By 1958 Professor D N de G Allen and D W Windle of Sheffield University were working with BR on the use of aluminium in railway rolling stock. They presented a paper at a joint meeting between the Institute of Locomotive Engineers and the Aluminium Development Association in 1960 entitled ‘Stress determination in coach frames by electronic computation’. A computer programme was used for calculating deflection under load in the development of the BR Mark II coach – which first appeared in 1963 and which was at the heart of the new ‘brand’ that BR developed at that time: ‘InterCity’.[41]

‘InterCity’ was very much in line with the aspirations of an era often summarised by quoting from Prime Minister Harold Wilson’s speech at the Labour Party Conference in 1963 when he mentioned ‘the white heat of technology’.[42] In the previous year BR had put plate glass windows in their offices on Euston Road, to show off their new computer, a Pegasus 2, believed to be the first digital computer in the world to produce a railway timetable.[43] At the time BR’s customers were more likely to notice the electrification of the West Coast Main Line to Liverpool and Manchester (a change which saw Stanier’s express steam locomotives withdrawn from service) than consider how the printed timetable was produced.

Meanwhile experience with Hollerith machines on calculating payroll continued to progress. In 1957, BR Western Region purchased a BTM 1201 (a ‘Hollerith Electronic Computer’ 4[44]) for processing 11,000 weekly pay packets in the London area. BR Eastern Region bought a similar machine for Darlington in the following year, used for weekly payroll for 40,000 traffic staff.[45] Whilst the processing of wages by computer was well established it would be some while yet before the weekly pay packet disappeared. At that time BACS did not exist, and the railway had wages clerks deliver wage packets by handcart to stations, or even by light engine to remote depots, despite how ‘modern’ the method of arriving at the amount that had been counted into the wage packet was.[46] British Railways also hedged their bets on computer acquisition. During the 1960s they had ICL machines at Crewe and Peterborough, although Peterborough was purely an operations centre.[47] Everything was developed at Crewe first, and then taken over to Peterborough when tested.[48]

By the end of the 1960s BR had gone through the trauma of the ‘Beeching’ era, had abandoned roughly one third of the network, and got rid of all steam locomotives. It was pushing forward and (just as in the past) on the look-out for technology that could deliver efficiencies. Its staff included those whose professional career had included computer technology long before most of Britain’s workforce was aware of this technology; at the same time it still saw itself as a ‘wagon load’ freight railway as well as a railway for bulk cargoes, containers and passengers. British Rail was thus interested in, but also had the knowledge capital to examine, an American system for control of freight trains, even at a time when the UK government was backing a ‘Buy British’ campaign.

The US Southern Pacific Railroad’s ‘Total Operations Processing System’ (TOPS) (Kramer, 1966; TOPS, 1970) was a computer-based system, developed in collaboration with IBM. Despite its high cost, once fully implemented it was a means by which all of BR’s freight movements and all the individual wagons (over 300,000 at the time of its introduction) and their cargoes could be tracked in real time across the whole rail network. It used IBM 370 mainframe computers installed at Marylebone in London. It was a radical development that would change the way BR worked, as for the first time all freight trains could be tracked and BR knew exactly how many wagons it had, how many it needed and where they actually where. TOPS gave BR for the first time an asset register of rolling stock and its location in real time and as such was a system that would underpin privatisation when it came in 1994. By 1976, TOPS controlled up to 4,500 freight trains and 100,000 wagon movements each day across 11,000 miles of track. This amounted to tracking a million freight train miles a week across the system (Arnott, 1979, p 113). It was just the kind of innovation that John Aspinall of the L&Y would have approved of.

Despite its railway credentials, TOPS was a military-style centralised command-and-control communications and computer system, with antecedents in the Semi-Automatic Ground Environment (SAGE) – the Cold War early warning system for the United States of America (Aylen and Gwynne, 2019). When fully implemented TOPS relied on telecommunications to connect 155 Area Freight Centres with two IBM 370 mainframe computers at Blandford House, Marylebone. One computer was operational and one running as back-up. The twin technical breakthroughs in the adoption of TOPS at British Rail were the use of modems at either end of the phone line which allowed digital data signals to be transmitted down an ordinary phone line as an analogue signal, and the ability to multiplex these signals (a technique called ‘Frequency Division Multiplexing’ or FDM) which allowed up to eight separate signals to be sent down the same audio line at once (Boura, 1973; 1975).[49]

The use of FDM was essential to allow TOPS to work in the context of the British Rail telephone system (Reilly, 2004, p 228). Multiplexing allows a number of low bandwidth communications (such as a telegraph message or digital message) to be sent together over a high bandwidth channel, such as a telephone line. The use of FDM markedly increased the carrying capacity of British Rail’s telephone network (which had developed separately and remained separate from the domestic telephone network). As early as 1958 British Railways had used another form of multiplexing – ‘Time Division Multiplexing’ (TDM) – in a signalling application for remote relay interlocking as part of the electrification of the West Coast Main Line. This use of TDM allowed a signal box to be a long way from the junction it controlled and was claimed at the time as the first industrial application of the technology.[50]

TOPS not only brought a marked improvement in the use of assets, it also shaped the way in which the future railway would be organised and managed (see Figure 10). It represented a shift from a craft-based railway running on custom and practice to a modern management system and went fully live in 1975 just as the railways were celebrating the 150th anniversary of the opening of the Stockton and Darlington Railway (with a large cavalcade of mainly steam locomotives). TOPS evolved into the era of distributed networks and packet switching and is still with us today in the TRUST system used for monitoring the progress of trains and ‘delay attribution’ which allocates the costs of any delay amongst the companies running the network.[51]

The development of TOPS was also made possible by work on a nationwide network of co-axial cables for telecoms and data which was completed in 1972 as part of the BR National Telecoms plan. This scheme was followed in 1985 by BR laying fibre-optic cables to establish a high-speed communications network, one of the country’s first high-speed fibre networks, and years before ‘high-speed fibre’ became part of the conversation about communication in the age of the internet. By the 1980s the developing computer world was involved in every aspect of the way British Rail functioned, from calculating wage packets to vehicle design, from how signalling worked to experiments with automatic train control.[52] Passengers could also benefit from an ‘anywhere to anywhere’ ticketing system both at stations[53] and on trains, delivered by computer. In addition to timetables produced by computer, from 1972 there were real-time passenger information systems, first developed by Dina St Johnston[54] and team for BR Southern Region. By 1990 these ‘real time’ systems could be seen at over 400 stations.[55]

All of these systems pre-date the invention of the World Wide Web (even if systems like TOPS seem like older members of the same family). In addition, all of these systems (outside of those used in accountancy) were internal to the railway. They had no links to outside networks,[56] intentionally making them ‘tamper proof’ and safe. The railway is an industry where safety is paramount,[57] and where applications of electronics to signalling and control have always needed to be proven as safe in practice, and with a robustness that means it cannot easily be interfered with. This separateness is becoming a major issue as the railway embraces the digital revolution and starts to use the power of the internet. One of the sought-after benefits of moving in this direction is the ability to greatly increase the capacity of the rail network by controlling individual trains, rather than using a system that allows trains on individually controlled ‘blocks’ of railway. The introduction of this kind of system on London’s ‘Thameslink’ in 2018 proved what is possible. On that part of the network automatic train operation can handle up to 24 trains an hour (or a train every 2 and a half minutes).

However, the need to protect web connected systems from outside attack means that the railway is very careful in its approach. In 2017 a six-week project was run which created a virtual railway in a way that looked to on-line hackers like a real railway. ‘Project Honey train’ gained 2.74 million attacks in the six weeks it ran and has influenced the development of a rail cyber security strategy.[58] Today the union between rail and computer technology is seen as a marriage that is crucial for rail development in the twenty-first century but it comes about after more than a hundred years of technical development on both sides of the fence – it has been a long engagement.

Endpiece

https://dx.doi.org/10.15180/211603/005This paper argues that in combining approaches from railway history and the history of computing, a new story emerges of the railways’ early adoption and continued engagement with electrical technologies. In making this argument the paper necessarily covers a broad scope and timespan and can only begin to outline case studies. The adoption and development of technology within the railways is discussed here in relation to paying and managing a scattered workforce, ensuring efficiency of the business in delivering freight at speed, in research and development to understand wheel and vehicle design, and vitally to manage the safety of staff, goods and passengers on a complex moving network. If space allowed, elaboration of these case studies might make papers in themselves, for example in looking at control one might expand the case to look at railway management, and bureaucracy and the spatial, organisational and corporate dimensions of control within the railway environment. Additional research might focus on the adoption of North American practice in the UK, or turn in detail to the material culture itself to illuminate the physical manifestation of the control issues described above. The bringing together of (at least) two historical disciplines here underlines the author’s belief that these questions would benefit from the approaches of currently separate disciplines. Computer history, business history and museology studies have existing literatures on which to build and all have a welcome role to play in further unfolding the interwoven relationship outlined here and in so doing give railway history a more rounded form.

Acknowledgements

Colleagues in ‘Search Engine’ at the National Railway Museum, NRM volunteer Bruce McDougall and others, Jonathan Aylen, Manchester Business School, Nicola Forsdike, York University, Dr James Peters, Archivist, John Rylands Library, University of Manchester