Photography and electroplate in 1840s Birmingham

Article DOI: https://dx.doi.org/10.15180/232014

Abstract

Industrial improvements to silver plating through the work of electroplating firms such as Elkington, Mason and Co are an important part of our industrial heritage, bridging art, science and industry to form a significant portion of museum collections. However, the impact of this development of silverplating technology upon photography has not previously been explored. This article details the improvements that electroplated silver brought to the daguerreotype photographic process and to the manufacture of daguerreotype plates in Birmingham, offering a material reappraisal of the inventive qualities of the daguerreotype within a wider narrative of industrial manufacture.

Chemists in 1840s Birmingham were developing photographic techniques and silverplating processes at the Birmingham Royal School of Medicine and Surgery, later Queens College on Paradise Street. These scientists – George Shaw (1818–1904) and John Percy (1817–1889) – had detailed, tactile knowledge of the convergent chemistry and processes in both arenas. Developments in the industrial manufacture of silverplate in 1840s Birmingham created significant improvements to the materials used in the daguerreotype photographic process, making photography more viable as a commercial venture. Shaw planned an early portrait studio and worked with early innovators in electroplating techniques the Marrian brothers (Francis (1802–1893) and Benjamin James Pratt Marrian (1811–1891)) using magneto-plate technology developed by another Birmingham industrial entrepreneur John Woolrich (c. 1791–1843). This potential studio did not emerge due to restrictive patenting and licensing restrictions around the practice of daguerreotype photography, yet extant daguerreotypes tell a story of improvements stemming from technical innovation. These daguerreotypes situate industrial Birmingham as a place of innovation and invention and place the daguerreotype photographic process within narratives of industrial improvements and radically inventive manufacturing practices.

Key to the analysis presented here is the role of the recreation of historic techniques in historical research and the value of acquiring tactile knowledge of the behaviour of materials during the processes explored. Here practical experiments allowed the author to look beyond the surviving daguerreotypes via material knowledge to the circumstances and social environment of production. This approach revealed new knowledge which offers an alternative reading of the history of objects through their materials.

Keywords

Birmingham, collections, daguerrotype, Electroplate, Magneto, Manufacturing, objects, Percy, Practice-based research, Recreative practices, Shaw, Woolrich

Introduction

https://dx.doi.org/10.15180/This paper reveals how the skilful hands of a circle of chemists and manufacturers in Birmingham improved the materials used in daguerreotype photography in the 1840s. The work of John Percy (1817–1889) and George Shaw (1817–1904) on industrial improvements to the manufacturing process for silverplate had an important impact on the history of photography. These men were linked by their professional associations at the Birmingham Royal School of Medicine and Surgery (later Queens College) on Paradise Street but their impact on photography also depended on their networks within the contemporary metal trades of Birmingham.

In this period Birmingham was a centre for the manufacture of metal goods and innovations in electroplating metals were superseding established methods in this industry. These radical new manufacturing methods of electroplating originated in Birmingham and spread through the licensing of patents to other centres of the metal trades, such as Sheffield where they were met with resistance from established centres of traditional craft skills. Silverware and jewellery industries in the city were well established at this time and as such improvements to manufacturing processes were aimed at businesses that were already profitable as improvements in the quality and ease of manufacture, as well as a marketing tool that utilised technological invention to generate an air of superiority. The framing of photography within an environment of commercial and industrial practice in this paper situates photographic development as a product of industry and connects its materials with the work of industrial innovators. The importance of industrial manufacturing histories are beginning to be addressed by historians of photography (Tucker, 2019; Ryan, 2017; Hallett, 1986) and beyond in histories of science (Rossi, 2010; Wale, 2022). As demonstrated in this paper, this approach amplifies the working story of materials and their commercial value highlighting important and often overlooked information about the impact of networks within industrial places.

The working knowledge and practice of early photographic processes and manufacturing techniques were being challenged throughout the 1840s by restrictive patents (Dickens, 1850; Perich, 2021; Macleod, 2010; Arapostathis and Gooday, 2013). However, the group of enterprising scientists and manufacturers discussed here tenaciously persisted in their approach within a competitive, commercial environment to make high quality daguerreotype images by inventing new processes that escaped patent restrictions. The importance of the role of industrial capitalism in the early development of photography has been described extensively by Steve Edwards (2006, p 34), who states that the ‘gentlemanly framing’ of early photography neglects the role of invention within industrial capitalism which is a driving force in industrial Birmingham and fuels the developments outlined in this paper. However, the place of early photographic experimentation within the metal trades in Birmingham and the significance of inventive manufacturing practices upon the silverplate material of the daguerreotype has not previously been discussed. This article aims to address this issue by highlighting collaborative knowledge transfer in industry between scientists and a working community of practitioners.

By combining a close reading of original sources (such as correspondence, papers and image-objects held within museum collections[1] and private archives) with a recreative making practice, this research offers an understanding of the connections across industries and an appreciation of the material nuances offered by these technological advances.

While the original sources highlight a network of knowledge, some evidence is absent in the archives. There are several reasons for this. The close-knit, geographically-concentrated nature of the knowledge networks in Birmingham – the major institutions were physically close to manufacturing enterprises in the industrial city of the time which meant that documents weren’t always necessary for communication. Compare, for example, letters[2] between Benjamin James Pratt Marrian and William Henry Fox Talbot communicating over distance since Talbot was then in Lacock in Wiltshire. Commercial secrecy surrounding patenting practices and invention is another contributing factor to archival absences, along with the rapid pace of photographic improvements in this period. This paper demonstrates how recreative making practices offer a methodology to address these archival absences.

Photography and electroplating innovation in Birmingham

George Shaw reputedly made a daguerreotype in Birmingham within two days of Daguerre’s public announcement of the process in August 1839[3], a technical feat that was made possible by his networks within the scientific and manufacturing communities in the city (James, 2018). However, the daguerreotype arrived in public view in Birmingham two months later, on the evening of Thursday 24 October 1839. On this day enigmatic Frenchman M. Ste Croix (Wood and James, 1993, p 107), demonstrated this photographic process on clad silver plates to the city’s scientific men at the Philosophical Institution on Cannon St (1993, pp 107–108). In the following four days Ste Croix reached a broader audience including metallurgists and manufacturers through a course of lectures and private tutorials held at the Philosophical Institution.[4]

In tandem with the emergence of the daguerreotype as the dominant commercial photographic process, Birmingham was reaching the height of its powers of innovation in the manufacturing processes of electroplated metals. Daguerreotypes are produced using highly polished silverplate as a light-sensitive substrate. An image is formed by fuming the silverplate over iodine to create a light sensitive silver iodide surface that is exposed in a camera and then developed out over hot mercury fumes and fixed in hypo to make the image stable. Hence the material qualities of the silver image surface, its ability to react with chemicals and malleability when polishing are crucial to the smooth operation of the daguerreotype process and the quality of the image produced. In this study the material of the silverplate surface and its qualities reveals a rich story of industrial practices.

Work on electro-metallurgy by experimental chemists such as Shaw had clear industrial applications and new material manufacturing processes were quickly taken up by large manufacturing operations such as Elkington, Mason and Co on Newhall Street, a short downhill walk less than half a mile from Queen’s College where Shaw worked. New electroplating technology led to the production of electroplated silver with different material qualities to traditional clad plate, qualities that were intrinsically useful to the daguerreotype photographic process.

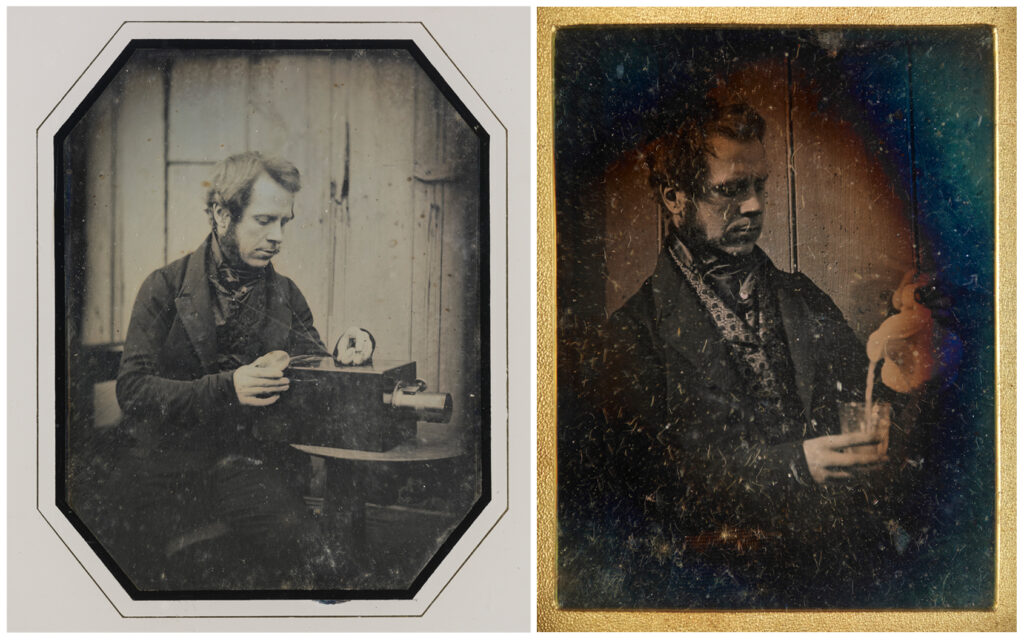

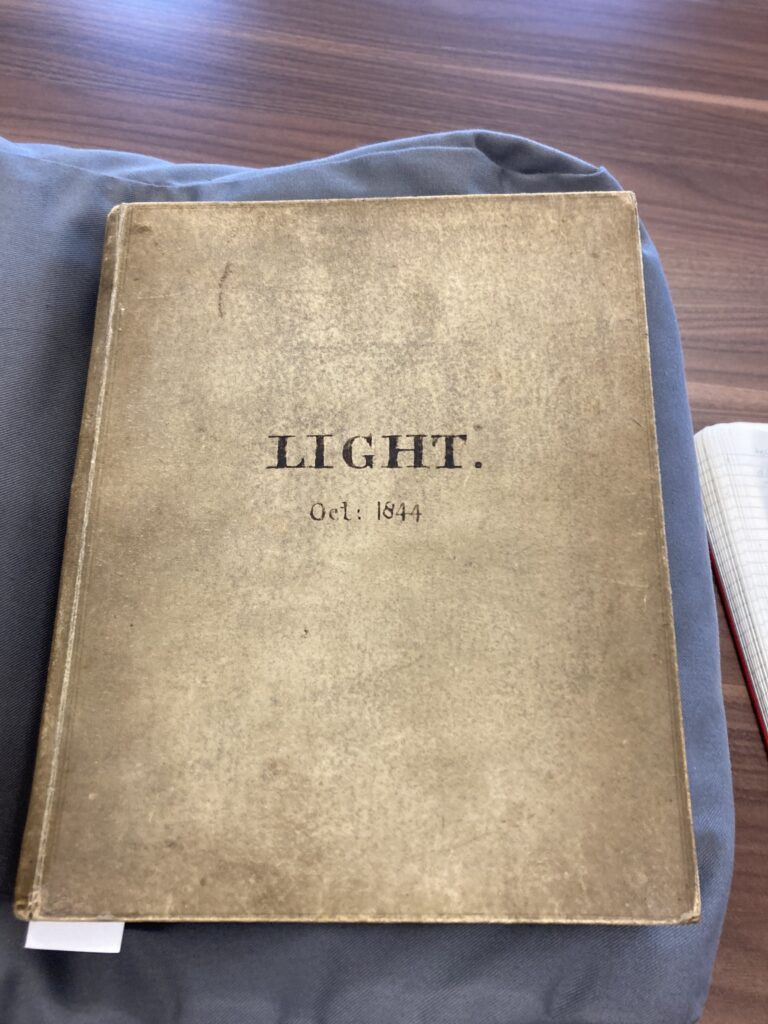

In the four years following his initial experiments with the daguerreotype, Shaw accumulated a high level of skill and tactile knowledge of the behaviour of photographic materials in both the calotype and daguerreotype processes. Circa 1843 Shaw produced daguerreotype photographs of Francis Marrian (Figure 1) that demonstrate his photographic activities in Birmingham and the speed with which he could make portraits. By this time, the daguerreotype process had moved on from Daguerre’s 1839 process with exposure times shortened by the addition of bromine vapour amongst other developments. But these objects show how Shaw’s work on electroplating offered further improvements.

In these images, Francis Marrian can be seen to be timing the exposures upon his pocket watch, whilst the act of pouring milk visualises the fast speed of the exposure times used in making these plates. Milk is deliberately chosen because of its colour, which is more visible in the image than water, and the natural form of the milk pouring is frozen in time. The distinctive frozen ‘V’ shape of the liquid form and the half-filled cup suggests a fast exposure time of less than two seconds. Francis Marrian remains sharp in the image – despite the action of pouring he has not moved during the exposure. This improved process and decrease in exposure time was significant in the practical business of photography and in running a commercial portrait studio as it requires much less skill and involvement from the sitter in holding a position. It makes the portraiture of young children and pets increasingly successful with less chance of a blurred image caused by the movement of the sitter. It would also make the process more convivial, removing the need for cumbersome and uncomfortable posing aids such as a head-brace.

This raises the question of how the material qualities of Birmingham manufactured electroplate made these high-quality images possible. The resulting material story also communicates the high commercial and social stakes that these images encompass. Daguerreotype portraiture was a valuable business prospect during the 1840s, with 15 Beard-licensee portrait studios operating as early as 1842 (Batchen, 2017), but was fraught with technical difficulties that could limit its profitability.

Shaw was working alongside his colleague Dr John Percy who was Professor of Organic Chemistry at Queen’s College in 1844 and later becomes well known for his work on industrial metallurgy at the Royal School of Mines, London. The two were seeking tactile, working knowledge of photographic materials through experiments which were recorded in Percy’s ‘Light’ notebook (Figure 2) now held in the archive at the Science Museum. This notebook details Percy and Shaw’s collaborative experiments into the light sensitivity of silver chloride under various conditions. John Spiller, Percy’s former assistant, described the notebook 1890 for the Photographic Society (1890, pp 120–125) and identified in it the advances in knowledge about the behaviour of light sensitive chemicals that were significant to the development of photographic processes. The notebook also offers a useful glimpse of the working relationship between Shaw and Percy, allowing a fascinating insight into the personalities involved and environmental forces at work in experiments to advance the light sensitivity of photochemical processes.

Percy’s notes are neatly ordered, written in a carefully controlled script at his desk at Queen’s College, with detailed descriptions of the weather and lighting conditions. In contrast, Shaw’s notes are pasted in at a right-angle in a cursive hand apparently written at speed.

The notebook details a wide variety of manufacturing information pertinent to mining, ozone and glass manufacture to name a small sub-section of the materials and processes that interested Percy across his lengthy career. These are dismissed by Spiller in a preface added to the notebook as later entries that ‘refer mostly to metallurgical specimens’. However, these notes illustrate Percy’s intimate knowledge of the materials of the daguerreotype in reference to the worked behaviour of silver and copper. They also place Percy at the centre of Birmingham circles of manufacturers of the time. This material knowledge and manufacturing network may not have related only to photography, but the successful development of photographic techniques depended upon their supporting structures. Within the notebook and collection of letters held in the Science Museum archive Percy traverses the manufacturers of the city from his central base on Newhall Street (next to the Mechanics Institute and close by Elkington’s factory), recording ‘useful and reliable information’ (Inkster, 2012) about the tactile nuances and details of manufacturing processes for metals and materials manufactured in the city. For example, ‘Marrian (the plater)’ is referred to in the notebook as providing information about methods of producing a ‘dead’ white colour of silver and avoiding a yellowish tint by preventing the acid liquor from dissolving the base copper during plating.[5] His brother, brass founder J P Marrian, offers details about alloys of zinc, copper and tin. He adds a small quantity of lead to tin for turning which makes a difference in ‘the working quality of the metal’. The turnings ‘leave the tool well’. However, Mr Clifford[6] informs Percy that lead in copper ‘throws up the silver’ during plating. These fragmentary statements join with other information mined from the archives and the ‘Light’ notebook itself to form a picture of Percy as someone completely embedded in the manufacturing community within the city – someone who had collaboratively sourced detailed working, tactile information about the qualities of silver and metal manufacture in the city which was pertinent to the manufacture and utility of daguerreotype plates.

The Marrian brothers provided a useful first-hand source for John Percy’s questions about the tactile qualities of metals within the ‘Light’ notebook as they thoroughly understand the nuanced qualities and potential of the metal materials that are the daily bread of their trades. ‘Marrian (the Plater)’[7] is Francis Marrian (1803–1893), the subject photographed in Shaw’s daguerreotypes above. Marrian was a sculptor, later a silversmith, modeller and plater based on Cannon St, Birmingham. He assisted with organising the 1839 exhibition at the Mechanics Institute, Newhall Street where his brother Benjamin James Pratt (J P) Marrian (1811–1891), George Shaw and John Percy held regular lectures,[8] along with other lecturers from Queen’s College such as John Barritt Melson and John Woolrich. The discussion, development and dissemination of innovative chemical techniques by this circle of networked individuals through educational institutions such as Queen’s College and the Mechanics Institute can be seen as an important factor in the inventiveness that existed in manufacturing within the city.

Competing processes of electroplating in Birmingham

This section discusses key technological developments that directly impacted the processes of daguerreotype photography, especially Woolrich’s magneto-plating machine. The chemical process allowed by this machine within the production of silverplate for the daguerreotype has been tested by the author in experiments described later in the article. Birmingham was the centre for invention in electroplating metals at this time and the stakes were high as photography offered huge commercial potential which was restricted by patents and licensing. In 1840 innovations by GP Dr John Wright (1808–1844) and George Richards Elkington in the use of potassium cyanide[9] as an electrolytic agent made electroplating possible. In the early 1840s John Woolrich Snr (1791–1843) developed a further significant invention in electroplating technology. This was the magneto-plating machine (Figure 4) which Woolrich’s son, John Stephen Woolrich (1820–1850) later patented. Woolrich Snr’s device improved the electroplate process by offering a continuous and consistent power source using an electromagnetic dynamo rather than unreliable early batteries. The magneto device created a consistent source of electricity using the principles of Faraday’s law of electromagnetic induction.

John Stephen Woolrich Jnr was a disruptive innovator within the circles of Birmingham manufacturers. In 1939, prior to his patenting of his father’s invention in 1842, he was pursued by Elkington and his licensees for patent infringement for having used Elkington’s electroplating processes, which was evidenced by Woolrich gilding a gold chain and earrings for Mr John Haseley.[10] Woolrich Jnr was under pressure to operate his machinery as he needed money to pay off debts incurred in its development and was in active competition with Elkington to license his magneto-plating process in Sheffield (Leader, 1913, p 26). The conflict between Woolrich and Elkington which is discussed below demonstrates the high stakes of industrial invention and illustrates the competitive and secretive nature of electroplate manufacture in 1840s Birmingham whilst underlining Woolrich’s position as an outsider to established hierarchies.

On 1 August 1842 John Stephen Woolrich filed patent 9431 for the use of his father’s magneto-generator machine for electroplating (Grant, 2014, p 77). This patent was controversial and was opposed by Elkington. In 1842 Elkington had acquired chemist Henry Beaumont Leeson’s patent number 9374, which specified the use of a huge number (430) of different electrolytic solutions as methods of electro-depositing metals and alloys (Grant, 2014, p 75). Woolrich skilfully navigated this expansive patent by specifying the use of a sulphite solution as a singular electrolyte, which is not covered in Leeson’s specification (Grant, 2014, p 76). Elkington later encouraged Leeson to adjust his specification to include this, but this was crucially after Woolrich’s use had been granted (Grant, 2014, p 76).

Woolrich’s machine is described by Shaw in his 1844 manual of electrometallurgy as ‘a discovery which promises to be of greater importance than any with which the art has hitherto been enriched’ (1844, p 15). The potential commercial value of this machine is evidenced in the industrial application of electroplate technology to the manufacture of silverware by Elkington, Mason and Co at their Newhall Street factory and the licensing of the technology through a network of local, national and international manufacturers.[11] Shaw claimed in his manual that Woolrich’s machine has an important commercial value as an improvement of this process with the ability to make existing electroplate processes increasingly viable with a constant power source in the magneto, a claim which is refuted by opposing sources.[12]

Alistair Grant’s (2014) research into Elkington describes how the innovations in electroplating used at Elkington’s factory and a knowledge of the income generated by John Wright’s earlier patent deal with Elkington for the use of potassium cyanide as an electrolyte was evidently known to John Stephen Woolrich. He approached Charles Askin, the same intermediary and adviser as Wright, to broker a deal for the commercial application of his magneto machine with Elkington in January 1843 (2014, p 78). However, Elkington did not buy into Woolrich’s invention until several years later. Perhaps this was due to a strained relationship with Woolrich over earlier litigation,[13] or as Robert Hunt suggests: ‘The magneto-electrical machine is employed in Birmingham for this purpose; but I am informed by Messrs. Elkington that they do not find it economical, or rather that the electro-precipitation is carried on too slowly’ (1854, chapter ix, footnote 167).

The uneconomic nature of the magneto machine was mentioned in Elkington’s speech at the 1849 Exhibition of Arts and Manufactures in Birmingham and was decisively described in period literature when its use is questioned:

Altogether, the magnetic apparatus appears to be a most preposterous application. It is costly and cumbrous – requires to be kept in constant rapid motion at a great expenditure of power – and, after all, does not increase the efficacy of the electricity one iota; but, on the contrary, much diminishes it. We are at a loss to conceive what may be the purpose of this expensive waste of electricity, except it is to astonish and captivate the ignorant by the display of an intricate machinery (The Artizan, 1843, p 133).

The spectacle of technological invention as seen in Figure 4, theatrically demonstrated by the magneto device, is key to both its fascination and to the appeal of photography in the 1840s. The magneto provided a visual and sensory display of technical innovation and carried a futuristic aura of invention that appealed to the public imagination. Importantly, the spectacle of the magneto made the process of magneto-plate appear to be dramatically different to existing methods of electroplating, therefore allowing for the circumvention of patent restrictions on existent methods of manufacturing silver plate. The Times articulated this on Saturday 15 April 1843, comparing Elkington’s patent favourably in relation to Woolrich’s innovation as a ‘counter patent’ with the ability to ‘seriously invade […] the very successful process of electro-plating and gilding patented by Messrs. Elkington, of Birmingham’. The article concluded with the following statement: ‘Nothing can more fully establish the absurdity and gross injustice of our patent laws than the above.’ This clearly establishes Woolrich’s invention as a means of disrupting patent restrictions.

The development of new technologies both in electroplating and photography were fraught with difficulties imposed by patent restrictions in the 1840s. However, patents were not always restrictive. Christine MacLeod explains how the ‘paradoxes of patenting’ resulted in various approaches to diffusion of technological advances by inventors navigating the system and challenges the assumption that all patents inhibited diffusion (MacLeod, 1991, p 887). Woolrich’s approach to diffusing his patent was through licencing, although he also retained a licence to work the patent himself, occupying a middle ground between the representation of a ‘product invention’ and a ‘process invention’ (1991, p 887). Elkington’s patents for electroplating operated in the same way, prompting Elkington to act to protect his licensing interests.[14]

Woolrich was undeterred by Elkington’s reticence to invest in the magneto-plating patent and his denial of any potential advantages of the technology and persisted with his approach. In April 1843 he offered to sell his patent for £15,000 (Grant, 2014, p 78). As an independent outsider to the commercial enterprise and large-scale operation of Elkington, Woolrich had over-estimated the value of his invention and the available capital of Elkington. Shaw’s claims within his manual[15] that his father, John Woolrich Snr was the true originator of electroplating provides some context for Woolrich Jnr’s bold assertion of a high value for his invention. Woolrich’s approach was declined by Elkington who then struck a ‘threatening note’ (Grant, 2014, p 79) by suggesting that Woolrich’s patent infringed his own acquisition of patents related to electroplate. This series of events echoes earlier litigation between Elkington and Woolrich in 1839,[16] illustrating the competitive nature of commercial industrial processes in 1840s Birmingham.

Woolrich’s magneto-plating machine was put to industrial use in 1844 by metal plater Thomas Prime (1797–1881). Prime operated a family plating business founded in 1818 which had previously employed traditional close-plating methods of manufacture. His ‘Patent Magneto Plate Works’ was on Northwood Street in Birmingham, a stone’s throw from Elkington’s Newhall Street works. Prime advertised in Shaw’s manual that his operation has been visited by ‘gentlemen of high scientific attainments, who have expressed their decided opinion of the beauty and superiority of the Magneto Process and its successful application to Manufactures’ (1844, p 205). Later visitors included Michael Faraday, who visited with John Percy and their wives Grace Percy (nee Piercy) and Sarah Faraday in 1845. Percy remarked that Faraday showed ‘sparkling delight’ (Grant, 2014, p 77) at seeing the practical application of his scientific principles. Correspondence reveals an ongoing working relationship between Percy and Faraday, illustrating the reach and importance of both this regional network and of Woolrich’s invention.[17] It was later recalled in Shaw’s obituary notices that Faraday commented to Percy that in comparison to George Shaw ‘In many things I am to him a child’.[18] This high praise perhaps stemmed from this viewing of the application of his high scientific thinking to a practical, industrial process and Shaw’s reputed technical knowledge of these manufacturing processes which is evidenced through his ensuing long career as a patent agent.

Francis Marrian’s younger brother Benjamin James Pratt (J P) Marrian (who worked as a diesinker – engraving dies or moulds for coins – and as a brass founder) wrote to The Philosophical Magazine about the ‘sonorous phaenomena in electro-magnets’,[19] a discovery which Percy mentioned in a letter to Faraday (letter 1629, p 264). In this letter, it was clear that Faraday had met J P Marrian when he visited Birmingham and saw Thomas Prime’s magneto-plating establishment, viewing Woolrich’s invention in operation. Through his detailed observation of the sounds of electromagnets it is evident that J P Marrian had worked extensively with a magneto, the key element of Woolrich’s invention, and we know from Percy’s ‘Light’ notebook that his brother Francis Marrian was an electroplater. The combination of the brothers’ skills in electroplate and the use of a magneto made them ideal candidates to put into practice John Woolrich’s invention of magneto-plating.

Improvements to the daguerreotype

Robert Hunt (1807–1887) in the Poetry of Science had pointed to a slow deposition of silver as the contributing factor to the magneto machine’s uneconomical use in Elkington’s commercial plating operation. Recent practice by Mike Robinson (2017) has shown that this slow deposition which occurs when plating at a low voltage is key to the surface quality of the silver in its application to photography. Slow deposition of silver during the electroplating process produces a softer surface which offers two important improvements to the daguerreotype. Firstly, the softer surface of the plate polishes more readily, reducing the laborious process of plate polishing – a distinct advantage in terms of the labour employed within a photographic portrait studio in the 1840s. Secondly, the slower deposition of silver with Woolrich’s magneto produces a larger grain structure on the silvered surface. This produces a layer with a larger surface area, allowing for a faster exposure time due to increased sensitivity to photographic chemicals. Mike Robinson has explained how this operates in terms of a galvanised layer upon the clad daguerreotype plate.

Fine grained hard silver deposits, […] are more wear resistant and appear more intensely black when polished. While this is beneficial for tableware, harder silver also retards photographic sensitivity […] galvanising performed at low current densities produces very soft and large grained deposits. Soft and large silver grains provide an increase in photo-sensitivity (2017, p 132).

This explains why Woolrich’s device which operated slowly at a low voltage was not ideal for the manufacture of tableware, which was a mainstay of Elkington’s manufacturing, as the softer silver produced at a low voltage would wear more readily. Electroplate manufacturing techniques offered increased speeds of production which radically transformed outmoded clad or fused-plate methods of production for consumer items such as tableware in manufacturing products that were accessible to an emerging middle-class consumer market. However, production using electroplating techniques with ‘self-acting’ chemicals and machines was resisted by traditional platers who were being deskilled (Grant, 2014, p 64) and questioned their qualities. Therefore, it can be seen that the material qualities of Shaw and Marrian’s daguerreotypes were improved as a result of technological advances in manufacturing resourced by industrial capitalism that were not primarily aimed at photographic use. The advantage of electroplate to photography occurred because of Shaw and Marrian’s position within the innovative metalworking centre of Birmingham. These incidental improvements to photography through industry illustrate how photography is part of a broader picture of advancing technology and manufacture which disrupts established processes and hierarchies.

Photographic plate for the daguerreotype produced with the Birmingham process of magneto-plating, making use of Wright and Woolrich’s innovations, was ideally suited to the commercial application of portraiture in the 1840s. This improvement to the silverplate for daguerreotype photography was a consequence of competitive industrial processes and licensing restrictions between Elkington and Woolrich. Increased photosensitivity of the plate resulted in faster exposure times that required less light, allowing for photographers to make portraits in unfavourable lighting and weather conditions and of commercially desirable subjects less able to sit still, such as small children and pets.

Mike Robinson (2017, p 90) has also noted that in early demonstrations, clad or fused silverplate procured in London by chemical supplier and analyst John Thomas Cooper (1790–1854) did not answer well to the image-making process since impurities in the silver resulted in an indistinct, flat, grey image. Cooper was an influential lecturer in chemistry at the Russell Institution and managed the laboratory at the Royal Polytechnic Institution and thus had access to industry-standard qualities of chemical materials at this time. Metallurgist Hugh Lee Pattinson similarly experienced issues in making daguerreotypes which were caused by impure silver.[20] The failure of images caused by an impure silver surface is removed as an issue by the Birmingham electroplating processes as electroplating crucially deposits pure silver upon the plate’s base metal substrate.

The benefits of Birmingham manufactured daguerreotype plate were noted in the Photographic Journal in a discussion about the plates in use during the 1840s, which took place after a meeting of the Photographic Society in 1890. Here two photographers who had worked with the daguerreotype during the Daguerreian era, Valentine Blanchard (1831–1901) and William England (1830–1896) reminisce about the qualities of the silverplate. Both photographers had lived, professional experience of the processes in use – William England began his acclaimed photographic career as an assistant in a Daguerreian studio in the 1840s and Valentine Blanchard began operating the daguerreotype process professionally c. 1854.

Mr W ENGLAND : There were two kinds, one the electro-plate, and the other the hammered plate.[…] The electro plates seemed to give brighter and better pictures.

Mr V BLANCHARD : […] Those made at Birmingham were silvered on both sides. The results on the electro plates were certainly finer (1890, p 125).

This experience was confirmed within the manual of Baron Gros, which detailed the daguerreotype process in 1850. Here the benefits of re-silvering used plates electro-chemically to obtain more reliable results were described and the author specifically mentions that plates manufactured by ‘M.Christofle’s atelier, and those that were given to me to try, gave me very beautiful images’(1850 p 6). In 1850 Christofle was using Elkington’s processes to electroplate under licence including earlier innovations by Woolrich and Wright.[21]

Pete James has stated in the History of Photography journal (James and Wood, 1993, p 111) that:

In 1839, Birmingham was a major centre for the manufacture of the plated metals subsequently used for the production of daguerreotype plates. It was also the focus of research and development work into the new plating technologies that were subsequently used for coating and copying daguerreotype plates in later years (1993, p 111).

It can be concluded here, building on James’ earlier research, that the new plating technologies referred to are the innovations by Wright and Woolrich in the city. Crucially, these technologies can be seen to subtly change the surface qualities of the silverplate in a material nuance which offers significant improvements to the daguerreotype process.

Recreative practice

The importance of these subtle yet significant differences between materials manufactured with varying means of plating would be impossible to perceive solely through the handling of surviving daguerreotypes of the period and their contextualisation within period literature. In this study, the working qualities of these materials have been tested through their handling during the performance of historic processes. This re-creative methodology builds upon methods used by Mike Robinson in his study of the daguerreotype (2017) and Pamela Smith’s Making and Knowing project (2014) amongst others (Sibum, 1995; Nasim, 2019; Osterman, 2011). It utilises Tim Ingold’s (2007) conception of materiality as the changeable stuff of objects in response to environmental conditions.

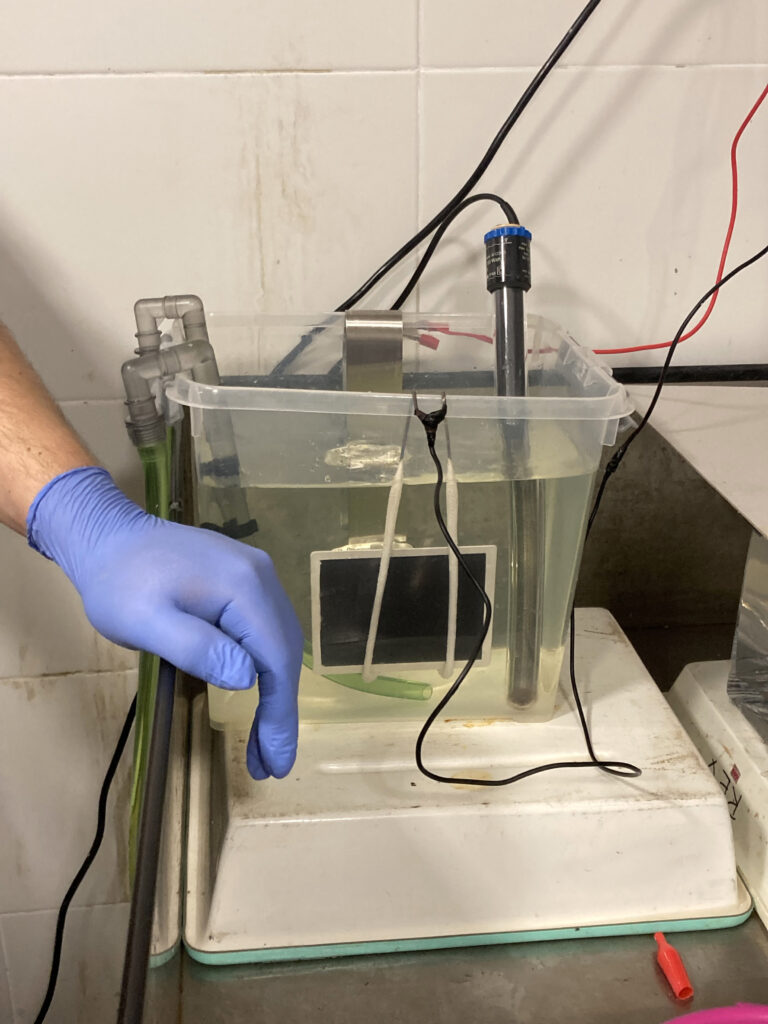

My recreative practice aimed to establish tactile knowledge of the behaviour of materials during the daguerreotype making process. To do this I performed comparative experiments to test the handling of plated silver manufactured with both a cladding process and using electroplating. This was done collaboratively with Joaquin Paredes Piris at Analog Inside Lab, specialists in historic photographic processing in Cáceres, Spain.

The cladding process traditionally used to manufacture silverplate, and used to form early daguerreotype plates, involves a sheet of silver in a solid state which is annealed and passed through rollers to bond onto a substrate of copper to form the silverplate used as a surface for the daguerreotype. In contrast, during electroplating the silver is in a liquid form which bonds to the base substrate (traditionally copper, but in our experiments we used brass) by the action of an electrical current. Electroplating at a low voltage therefore offers a slow, fluid bonding of silver particles through electromagnetic forces. These move silver particles through an electrolytic solution from the silver anode to the substrate of the metal plate on the cathode rather than using the heat and pressure which bonds the silver to the substrate during the cladding process. Jane Bennett’s new materialist text, Vibrant Matter (2010, p 59) offers a way into the differences in the poly-crystalline material grain structures of metals. She describes the poly crystalline grain structures of metals with intercrystalline spaces as a ‘variegated topology’ which dictates the material’s properties that are exploited by metallurgists. The topology of electroplated silver is a looser, more fluid structure with larger grains and more gaps than that of the rolled, compressed grain particles in a clad plate and as such the former softer surface is more receptive to processing and chemical reactions than the harder metallic grain structures of a clad plate.

Historic daguerreotypes were usually small, cased items to be viewed intimately in hand-held cases. During my experiments, six new, small daguerreotype plates were produced measuring 7cm x 8cm by electroplating silver onto a polished surface of brass using a pure silver anode and an electrolytic solution of silver nitrate and potassium cyanide at varying voltages from 0.5v up to 3.5v. These varying voltages imitate the effects of the magneto machine which is criticised in the period text analysed previously as having a slow rate of deposition. They would thus be operating at a low voltage in comparison to battery powered electroplating which Elkington describes as faster and more economic – therefore operating at a higher voltage.[22] In addition to these tests of plating at varying voltages, three larger, 12cm x 15cm plate-sized daguerreotypes were made using electroplating at voltages from .8v up to 3v that were compared to three clad plates produced of the same size. The results showed that the electroplated silver polished more readily than the clad plates and that the surface was much softer and finer when plated with a low voltage in comparison to electroplate produced with a higher voltage. Further, results demonstrated more consistent and faster exposures upon the electroplate materials, due to the pure silver deposited and its larger grain structure. These recreative experiments therefore show that magneto electroplate offered a functional, high quality image surface which improved the daguerreotype. This is illustrated in Figures 6 and 7 below showing the difference between daguerreotype images madeusing clad and electroplated plates.

Patent magneto silverplate, as produced from 1843 in Birmingham offered three significant advantages to the daguerreotype process in comparison to both clad silverplate and standard electroplating techniques in use at the time, which used a higher voltage and faster rate of deposition: it was softer, purer and more photo sensitive.

A cutting-edge magneto-plate photographic studio?

The actors of the time understood the implications of new electroplating techniques on photography including the commercial ramifications. In correspondence with William Henry Fox Talbot (1800–1877), British inventor of the calotype photographic process, J P Marrian requested the terms for an exclusive license to operate as a portrait photographer in Birmingham under Talbot’s patent on 20 March 1843.

I beg to be considered in treaty for the exclusive right of practising your process in Birmingham […] An agent of Mr Beard is taking portraits here under his patent but with what success I cannot exactly tell – I think however not very great – Mr M. of Cannon St is a Brother mine [sic] a silversmith & plater and I think is still open for an arrangement for electroplating – the patent of Mr Woolrich is creating quite a sensation among us.[23]

This letter suggests that J P Marrian was considering the commercial application of Woolrich’s sensational magneto-plating device. In further letters he requested a meeting with Talbot in Bath to discuss his business plans. Approaching Talbot with the intention of making use of a license for his photographic process and mentioning the patent of Woolrich’s magneto process in the same letter suggests he was speculating about the potential use of the magneto process to produce photographic plates. Following Woolrich’s earlier experience of Elkington’s litigation surrounding the use of electroplating, the cloak and dagger nature of Mr J Haseley’s entrapment of Woolrich, and evidence of communication between Mr Haseley, Talbot and Elkington,[24] there is good reason for this ambition not to be communicated explicitly within J P Marrian’s letters.

The complex entanglement of chemical patents around photographic practices and electroplating which Shaw and Marrian were navigating during this time can be further illustrated in the following examples, which entwine early photographic inventors with electroplaters in a web of licensing processes. Photographic businessman Richard Beard (1801–1885) dominates the field of commercial photographic portraiture in England as he purchased an exclusive license to operate Daguerre’s process. Beard also purchased Elkington’s patent to gild photographic prints in 1841 (Leader, 1913, p 33). Under a patent of 9 December 1841, Talbot was the patentee of the application of hyposulphite of soda, or hypo, used to fix photographic prints. In 1842 Talbot also patented several improvements to the electroplating process, including the use of photographic developing agent, gallic acid, in the silver solution, and dissolving chloride of silver in hypo.[25] In 1844 Elkington paid Talbot £500 so that they could use hypo within Siemens process for electroplating.

The tangle was this – Elkingtons [sic] were advised that Talbot could not use his particular solution without terms from them, and that Siemens could not use his variation of the hyposulphite of Soda without making terms with Talbot (Leader, 1913, p 27).

This brief sketch of a sample of entangled patents shows the overlap of people, processes and materials involved in the industrial process of electroplating and photography. It further explains how subtle changes in manufacturing processes could be used to circumvent patent restrictions and fees, as in the case of Woolrich navigating Elkington’s patent for electroplating by replacing battery power with that of a magneto and one different electrolyte in the plating solution. Thus, Woolrich’s patent to produce magneto-plate for daguerreotypes as a new photographic process, free of existent restrictions on the daguerreotype, was most likely seen as an extension of these photographic-electroplate patent tangles and a viable proposition for licence-free commercial practice of photography in Birmingham in 1844.

The restrictions of early patent licencing around photography limited the practice of portraiture and the development of photography throughout the 1840s, prior to patent reform in 1852. It could be suggested that the Marrian brothers utilised George Shaw’s expertise as a patent agent in an attempt to circumnavigate Richard Beard’s licensing agreements with Daguerre on commercial British photographic practice. Or perhaps this series of events at the beginning of Shaw’s career as a patent agent sparked his tenacious interest in patent law and career as a patent agent.

Portrait photographer Joseph Whitlock[26] carried an exclusive licence from Beard to operate the Daguerreotype process in Birmingham at this time. Woolrich’s magneto plating device had been previously shown to have the ability to circumnavigate patent licences in electroplate and it was conceivable that it could be used in a similar way to produce a new magneto-plate photographic process that could negate Whitlock’s monopoly on making portraits in Birmingham. However, in 1843 J P Marrian was unfamiliar with the practicable details of Talbot’s photographic process on paper as he planned on ‘devoting a few hours every day to the subject’ and requested to learn the process through ‘a personal interview with you as an authorized person as being the shortest and surest method of arriving at perfection in the manipulation’.[27] Here the flaw in the Marrian brothers’ intention to begin a magneto-plate photographic studio in competition with Whitlock became apparent. J P Marrian seems to have misunderstood the reach of Beard’s licencing of the daguerreotype process to produce photographs upon metal plates and is unfamiliar with the details of Talbot’s process on paper. This renders the Marrian brothers’ knowledge and ability to produce high quality metal magneto-plate portraits using Woolrich’s process unworkable with Talbot’s patent and no further evidence exists of their potential portrait studio becoming a going concern. The details of Talbot’s calotype photographic patent for images made on paper did not allow for the use of the brothers’ expertise in the metal trades of Birmingham and Shaw’s knowledge of electrometallurgy which were crucial to the viability of their plans. The cutting-edge Birmingham magneto-plate photographic portrait studio which Shaw’s daguerreotypes of Marrian pre-figure (Figure 1) remained the spectre of a potential history. It was not until Frederick Scott Archer published and made freely available the wet plate collodion photographic process on glass in the early 1850s, and that the wet plate process is proven in the case of Talbot vs LaRoche (1854) to be beyond the scope of pre-existing photographic patents, that a wider and more experimental commercial practice and development of photographic processes such as that practiced by Shaw and the Marrian brothers was legally practicable in England.

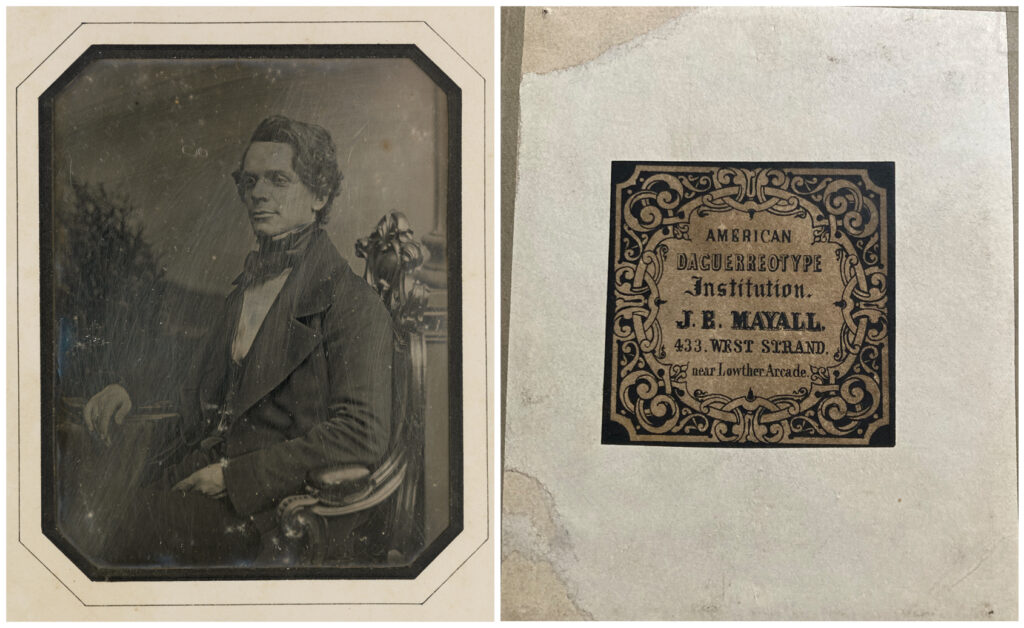

Whilst this potential cutting-edge Birmingham portrait studio was not to be, in Philadelphia, Oldham-born photographer John Jabez Edwin Mayall (1813–1901) was running a successful commercial practice as a daguerreotypist, unfettered by the English patent restrictions around Daguerre’s process. In 1846, Mayall came to London initially to work with Antoine Claudet (1797–1867) who had a unique early licence for the daguerreotype from Miles Berry, prior to Richard Beard’s acquisition of Daguerre’s invention.[28] Upon setting up his own daguerreotype institution at 433 West Strand, Mayall fell foul of Beard’s maintenance of his patent licences, admitting to Thornbury that he was ‘fighting the battle of the patent rights of the daguerreotype’ (1877, p 351). He was lent £300 by the landscape painter J M W Turner, which allowed him to overcome these difficulties and continue his photographic practice.

Renowned photographer Antoine Claudet was operating as a middleman for Birmingham manufacturers Chance glass, advising on the importation of technology to their Birmingham works along with his colleague, Georges Bontemps, who was invited ‘to perfect the optical glass’ at Chance’s works in Smethwick, near Birmingham (Cable, 2016, p 194) where he also advised on the flattening of sheet glass. Both activities were crucial to the photographic process, further highlighting the importance of Birmingham as a centre for photographic manufacture and materials, this time in communication with scientific developments in Paris. Chance glass were exporting materials internationally, selling glass flints for lenses to leading lens makers Voightlander and other photographic opticians. Trade links between manufacturers in Birmingham and Paris have been shown to have also been important to Elkington’s where French designers added skill and cachet to their designs (Grant, 2014) and this knowledge transfer between cities was also at work in the development of the daguerreotype through a network of well-connected businessmen such as Claudet. The transfer of information beyond the confines of geographically siloed knowledge conjures a metaphor of a connected electrical cell of material and manufacturing knowledge in the city of Birmingham. This connectivity is illustrated later through the documented manufacture of electroplate for the daguerreotype using Elkington’s techniques under licence by firms such as Christofle in Paris.[29]

In 1846, while still in Philadelphia, Mayall wrote to George Pyle, a photographer who he has recently instructed in the daguerreotype process that:

nothing fresh has turned up of any consequence, except that a new quick plate, much easier manufactured than the one I gave thee & will answer just as well (Robinson, 2017, p 12).

This new manufacture of a quicker plate may refer to the new magneto-plate which George Shaw potentially brought from Birmingham to be tested in the portrait below, a picture of George Shaw taken by Mayall at the American Daguerreotype Institution in London circa 1846. Mayall’s advertisement in The Times (1847) places emphasis upon ‘NEW DISCOVERIES IN DAGUERREOTYPE with a degree of delicacy, depth of tone and lifelike reality never previously attained’. These qualities match the visual evidence that exists of extant daguerreotypes made on pure silver deposited via electroplate.

This portrait of Shaw (Figure 8) dates from late 1846 and marks the beginning of an ongoing photographic relationship between Shaw and Mayall. Shaw returned three years later to Mayall’s studio and the portrait was recreated as an ambitious, large-scale daguerreotype (Figure 9) on an outsize plate measuring 48cm x 58cm. The scale of this image was made possible using a mammoth lens which Mayall described purchasing in Thornbury’s The Life of JMW Turner: ‘at the time I was a struggling artist, much devoted to improving my art, and had just bought a large lens from Paris, six inches in diameter’ (1877, p 262). A lens of this size would have been made in Paris utilising the improvements to the manufacture of optical glass which Claudet imported to Birmingham from Paris for Chance glass via the expertise of Georges Bontemps in June 1848 (Cable, 2016, pp 194–195).

This daguerreotype was chosen for exhibition by Antoine Claudet at the 1849 ‘Exhibition of Manufactures and Art in Birmingham, in Connection with the Meeting of the British Association’.[30] A forerunner to the Great Exhibitions of 1851 and 1862, this international exhibition in purpose-built Bingley Hall in Birmingham was produced for the 1849 meeting of the British Association. Alongside Robert Hunt, George Shaw was secretary of the association and was a key figure in the organisation of the exhibition. The ambitious scale of this daguerreotype and its grandiose frame are evidently selected to raise the attention and profile of the manufacturing processes and improvements made to the daguerreotype in the ten years since the invention.

First-hand inspection of this image-object in the archive at the National Media Museum revealed that it is made on a sheet of electroplated silver. Given Shaw’s involvement in both the image and the organisation of its exhibition in Birmingham, the plate material is likely to have been manufactured using Woolrich’s magneto-plating process in Birmingham, perhaps by the Marrian brothers at Thomas Prime’s works. Unfortunately, this information was not recorded in the exhibition catalogue, a fact which is criticised in Robert Hunt’s review of the exhibition for the Art Journal.

we feel again called upon to remark upon the impolicy and injustice of permitting mere dealers to contribute articles in their own names; thus depriving the actual manufacturer of that honour.[31]

Period press articles describe how the scale of this daguerreotype negates the intimate reflection of blacks into the daguerreotype, making the image hard to see.

We may not pass over without comment the admirable specimens of the Daguerreotype from the establishments of Mayall and Claudet ; it is only now that the pictorial effects of this invaluable art agent is being understood and its power demonstrated : ‘comparisons are odious’ on the authority of Mrs Malaprop: we, however, have but little fear of contradiction when we say that nothing is equal to the specimen shown by Mayall, we have not seen anything to come near the portrait of himself, it has all the effect of a mezzotint engraving ; the same artist exhibits the largest Daguerreotype yet made ; but it is by no means distinct.[32]

The ‘largest Daguerreotype yet made’ in 1849 remains in the collection of National Science and Media Museum in Bradford. Close examination of it shows that Shaw and Mayall recreated the smaller, earlier portrait with Shaw slightly aged by the distance of three years and much work between sittings – he has lost some hair and gained a little weight. The image was probably intended to show off the extent of Birmingham metal plating technology and the mature development of photographic techniques at the 1849 exhibition. It represents the technology of the daguerreotype pushed to its limits as the reflections upon the large plate render it ‘indistinct’ and the difficulties in handling chemicals evenly at this scale has resulted in some areas of the image becoming slightly discoloured.

The increased photosensitivity of the magneto-plate, along with the ability of the huge lens to admit more light to the camera makes the exposure times for portraiture at this scale increasingly viable in 1849. The public appeal of the combined technological aura (Morus, 1993) of cutting-edge processes of photography and electroplate on a large scale made the spectacle of this exhibition piece compelling. It is significant that this plate, now cited as an example of photography reaching its maturity[33] is made on electroplate and shows George Shaw of Birmingham, patent agent and expert in electro-metallurgy.

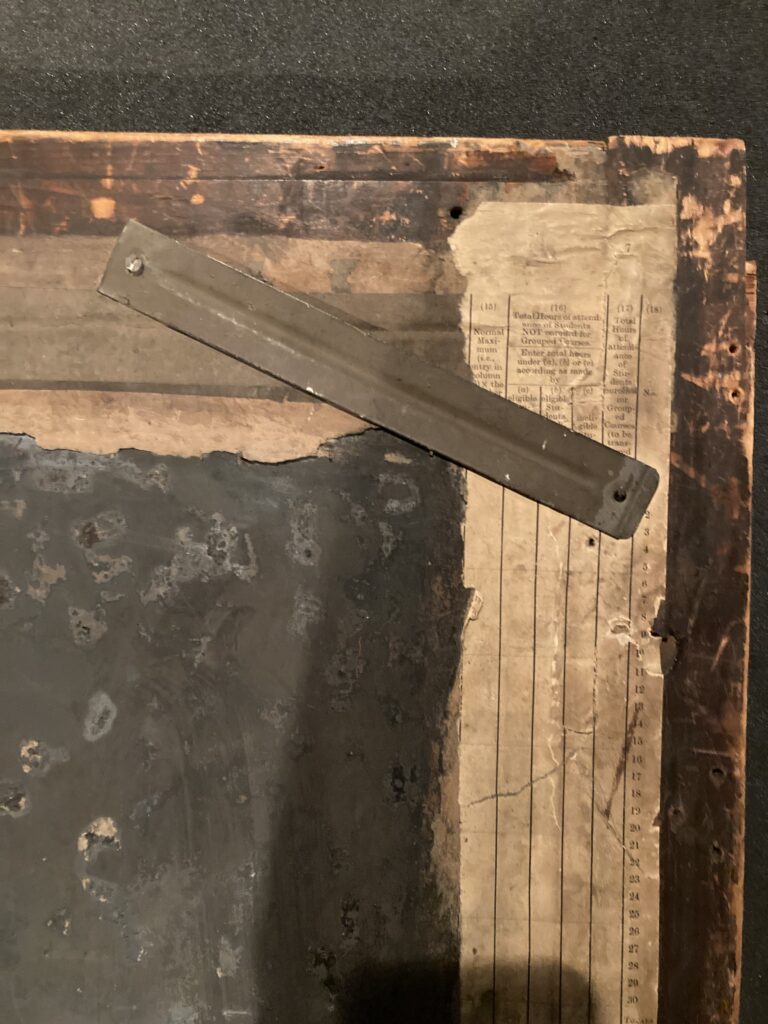

The rear of the plate (Figure 10) reveals the supporting ‘superstructure’ (Talbot, in Siegel, 2017, p 101) that has made this image possible, as the frame is supported both by robust, industrial metal brackets and papered with nineteenth century attendance records from an educational institution. These institutional documents visually show the support of educational institutions in nineteenth century Birmingham in linking this group of scientists and manufacturers across the arts and industry within the city. Further, the role of such institutions in research and development, as well as making scientific education accessible to the manufacturers of Birmingham, was key to the success of Woolrich’s application of his invention, as it allowed connected networks of individuals to collaboratively develop the use of processes and materials.

Conclusion

The ambitious work of inventive electro-metallurgists in Birmingham upon the daguerreotype process resulting from competitive improvements to industrial manufacturing processes throughout the 1840s allowed the daguerreotype to develop into a mature, workable photographic process which was widely shared through an established network. The material story described here centres the work of the makers, the hands-on experimenters who were developing, handling and working with photographic materials in the 1840s.

A tactile, hands-on making approach to this research has revealed the working qualities of these metal materials which are central to understanding the improvements to photography offered by Birmingham-made magneto silver plate. This tactile methodology takes us beyond the ‘magical mind-dust’ (Ingold, 2007, p 11) of materiality to understand the material qualities of metals in the flux of a making process. It has the potential to operate beyond photo-history to impact wider museum practices in order to reveal the rich object histories of a broad range of manufactured objects held in museums and collections.