From Renaissance medals to the Jaguar E-Type car bonnet: mechanised production and the making of luxury goods

Article DOI: https://dx.doi.org/10.15180/211606

Abstract

It is often assumed that the development of mechanised production technology and the making of luxury goods are incompatible. Arising from familiar narratives of the Industrial Revolution and echoes of Arts and Crafts thinking, high volume commodities are seen as the obvious domain for advances in mechanised production and high-quality luxury or semi-luxury goods are associated with traditional hand-craft methods. But innovations in mechanised production have sometimes been driven by the manufacture of luxury goods, not commodities. The technology which led to the pressing of the Jaguar E-Type bonnet began with the stamping of Renaissance medals, prestigious objects to bestow the favour of popes and princes. The major eighteenth-century advance in the making of three-dimensional objects in sheet metal from stamped components, a direct ancestor of twentieth-century car body manufacture, came from the Sheffield manufacture of luxury candlesticks and tableware, using silver-plated and silver sheet metal.

Keywords

eighteenth century, history of technology, industrial heritage, Industrial revolution, material culture

Introduction

https://dx.doi.org/10.15180/Jaguar Land Rover’s Classic division recently undertook a project for ‘continuation’ production of six Jaguar E-Type Lightweight racing cars, with aluminium bodies as built in the early 1960s.[1] The Jaguar company’s original E-Type car body dies had been disposed of long ago, so body panels for the new cars had to be made by hand-craft panel beating. However, the bonnet, a single piece of metal with a complex, sweeping shape that has always defined the E-Type in the public imagination, was considered far too large to create by hand panel beating. The bonnet could only be produced by the original mechanised method of pressing sheet metal into shape between an enormous pair of dies, in a hydraulic press the size of a small house. If original dies from the 1960s could not be found, then new dies would have to be made, adding cost and delay to production of the pre-ordered cars. Fortunately for the project, original Jaguar dies were found in the stock of a specialist car body component maker. These rediscovered dies were successfully used to make bonnets for the ‘continuation’ cars, 40 years after the last E-Type came off the production line.[2]

The die-stamping process has always been invisible to consumers, an unseen manufacturing activity. Nevertheless, in its mechanised form, it was and is a vital technology for the volume production of high design, luxury goods in metal, from Renaissance medals to the Jaguar E-Type.

Twentieth-century mass production of consumer goods has created the impression that advances in production technology are always driven by mass markets, where development costs can be spread over huge production runs. There is a complementary assumption that the making of high-quality luxury goods is the last bastion of hand-craft and traditional working methods. These assumptions are informed by the continuing influence of late-nineteenth century Arts and Crafts thinking, which prioritised hand-craft and associated mechanisation with a cost-cutting race to the bottom, morally and aesthetically, denouncing mechanisation as the enemy of quality. However, I will argue that the mechanisation of production technology has at times been led by the manufacture of high-quality luxury or semi-luxury goods, not mass market commodities. The development of mechanised stamping technology is an example of this, from Italian Renaissance portrait medals made with a screw press to English eighteenth-century silver candlesticks made by drop stamping in high relief, the forerunner of modern sheet metal pressing.

Stamping or pressing with dies to make ornamental metalware involves forcing thin sheet metal against a die made from a block of harder metal, usually with an intaglio image of the finished article carved – sunk – into the die block. Under pressure, the thin sheet metal takes up all the definition of the carved die. The stamping will emerge from the die like a jelly from a mould, as a cameo image, reversed left to right.

Something suitable has to be used to force the sheet metal against the die. The sheet might be pushed into an intaglio die by means of a pliable lead alloy ‘force’, a cameo made by pouring molten alloy into the intaglio die, thus avoiding the need to actually carve a cameo die to do the pushing. This method allows for very fine detail, as the pliable force is able to push the sheet metal into even the smallest, barely visible features of the die. Or pairs of dies may be used in combination, a cameo and an intaglio die, with an allowance for a thin gap between them, as with the Jaguar bonnet die set. The cameo pushes the metal into the intaglio bonnet surface die, while also smoothing and finishing the less critical appearance of the bonnet’s underside.

In the case of medals and coins, the metal sheet is forced between two intaglio dies, bearing different ‘heads’ and ‘tails’ designs. But medal and coin stampings are essentially flat pieces of metal with only surface decoration. So although both surfaces must be stamped in the same operation, with the dies applying equal force to the blank sheet in the middle, each side can look different without affecting the other.

Mechanised stamping can be used as an alternative to hand-craft embossing and chasing of ornamental metalware, where the design may be pushed out from the inside of the metal object with hammers and punches, then refined from the outside with smaller and sharper punches or even chisels. Some form of flexible resistance is used, such as a stuffed pad of leather or a resin block, to support the opposite side of the work to that being worked. Embossing and chasing is a lengthy process with variable results, depending on the skill level of the craftsman and the time allowed.

Stamping can also be a substitute for casting, which is less time-consuming than embossing and chasing, but does involve preparation of a mould and significant hand-finishing to achieve a high-quality result.

Relatively quickly, stamping can turn thin metal sheet into a shape equivalent to that of a hand chased or cast item, very precisely, with no hand-finishing and using much less metal.

And a well-stamped item will always reflect the quality and exact dimensions of the die, avoiding the variations and potential poor quality of hand work. In his reference work on Matthew Boulton’s ormolu, Nicholas Goodison comments on the drawbacks of hand chasing for the finishing of ornamental vase castings at Soho, highly inconvenient for a manufacturer set on volume production and repeat orders:

there was plenty of room for variable work between the different workmen. The outside measurements of ‘identical’ mounts are seldom exact. Far greater and easily detectible differences can be seen in the quality and style of the chasing. The cheaper vases were poorly worked in comparison to the finer things […] Differences in style can be readily seen by comparing the chiselling of the mounts on similar vases or even sometimes of similar mounts on the same vase (Goodison, 2002).

Mechanised stamping involved substantial investment in the initial set up of stamping machinery and equipment, and in the making of each die. But over a reasonably long production run, stamping has the potential to produce results of high quality, matching or exceeding hand-craft alternatives, at a lower cost per unit than with hand chasing or casting methods. The potential benefits of mechanised stamping were first explored and realised in the making of high-design luxury metalware goods, not commodities.

Of course there are many other drivers for the development of production technology in metalware and other sectors, not least the development of machine makers’ business and knowledge networks as recently highlighted by Gillian Cookson (Cookson, 2018). Perhaps the best-known instance of production technology development in history is the eighteenth-century English development of textile spinning and weaving machinery, which is concerned with the production of commodity cotton and woollen cloth, based on an extensive machinery making and development culture explored in Cookson’s ground-breaking study. Nevertheless, even in the textile sector, it could be said that one of the most transformative technologies ever invented, the Jacquard hand-loom controller of 1804, was driven by the needs of luxury fabric production – coloured silk woven in elaborate patterns, not plain cotton, although the Jacquard controller was later adopted in England for the making of patterned cottons (Science and Industry Museum, 2021). Not everyone will agree with writer James Essinger in his conclusion ‘that in essence a computer is merely a special kind of Jacquard loom’ (Essinger, 2004). But there is no doubt that the Jacquard controller transformed the making of patterned fabric, and this transformation was driven in the first place by the production of luxury cloth.

While by no means claiming that luxury goods have driven the development of production technology consistently across different sectors and periods, I will show that the making of luxury metalware has driven the mechanisation of production technology and that there can be a close relationship between luxury goods and mechanised production, a relationship that is too often overlooked.

I will argue that the most critical development in the history of mechanised stamping was the eighteenth-century English invention of drop stamping in high relief, used in the making of three-dimensional components for plated and then silver semi-luxury or luxury tableware. Drop stamping in high relief is the critical step from the use of dies to make flat objects such as medals or small low relief items such as buttons, to the making of components to construct complete candlesticks, tea caddies and other items of tableware. Drop stamping in high relief is the critical step between the making of medals and the making of car bodies, and it was driven by the production of luxury goods.

The beginning of mechanised die-stamping: Renaissance medals and the screw press

https://dx.doi.org/10.15180/211606/002It is sometimes assumed that hand stamping with dies began with the first coins in the sixth century BCE (British Museum, 2021), but Ancient Egyptian artisans were using hand stamps faced with dies to decorate gold jewellery in the twelfth century BCE (Flinders Petrie, 1909). By the same token, it is often assumed that mechanised stamping began with high volume coin production. However, stamping with a machine was first established with the Italian Renaissance production of medals, luxury or semi-luxury products, which could be made in gold and silver as well as base metals. Mechanised stamping, derided by the Arts and Crafts movement as a byword for low quality, began as a response to the limitations of hand tool methods for the volume production of high-quality semi-luxury goods – portrait medals of the Italian Renaissance.

The earliest Renaissance medals were made by hand hammering, as with coin production of the time (Scher, 2000). Hand hammering involves a firmly fixed lower die on which a blank is placed, with the upper die gripped in manually-held tongs and placed on top of the blank. The upper die is then struck with a blow from a heavy hand-held hammer, forcing the blank into shape between the two dies. Since the hand-held upper die cannot be kept in precisely fixed registration with the lower die, the obverse and reverse of the struck coin or medal will not be in exact alignment. Also because of the lack of fixed registration, the alignment will shift each time if multiple blows are applied, with even small shifts resulting in a blurred impression. So the size and depth of relief of the hand hammered medal is limited to what can be achieved in a single blow. These limitations constrained the making of portrait medals by traditional hand hammering.

A new indirect method of hand hammering was developed which allowed greater force to be applied, more evenly, by holding dies and blank together in fixed registration. Vasari describes how the dies, with the blank between them, are held inside a simple iron frame, with the dies sandwiched between a number of V-shaped (presumably wooden) wedges (Vasari, trans. 1907). The thick ends of the wedges are then hand hammered in sequence, many times, steadily forcing the dies together and impressing the blank. This indirect method of hammering, with the frame ensuring fixed registration, enabled the striking of larger coins and medals, but was very laborious, as Cellini tells us (Cellini, trans. 1898).

The best-known, largest and most impressive Renaissance portrait medals were made by casting, which by-passed the limitations of striking with dies. The medal casting process involved the effort of re-making the mould after two castings (Tuttle, 1987), and some hand-finishing of the casts to remove casting sprues and perhaps correct the casting in a few places; but medals were at least semi-luxury objects, so the effort of casting was acceptable.

However, increased High Renaissance demand for portrait medals, issued in substantial numbers by popes and princes as gifts to build support and recognition for the issuer,[3] prompted a search for production methods more suited to high volume than casting or the laborious frame striking method, without sacrificing quality.

Mechanised striking using the gearing advantage of a screw press emerged as the technology to overcome the limitations of hand striking. The concept of mechanised striking with a screw press is thought to have begun with Donato Bramante, architect and keeper of the seals for Pope Julius II. In about 1506, Bramante developed a screw press for the striking of papal seals in lead, possibly derived from the well-established use of the screw press to apply force in processes such as wine making (Cooper, 1988).

Vasari recounts Bramante’s various achievements in architecture for Julius II and how the pope rewarded him with appointment to the ‘Office of the Piombo [lead seal], for which he made a machine for printing [stamping] Bulls [seals], with a very beautiful screw’ (Vasari, trans. 1912). The screw press was a faster and easier alternative to casting a Bull, or bulla (‘seal’ in medieval Latin, from which the term ‘papal bull’ is derived) (Encyclopedia Britannica, 2015).

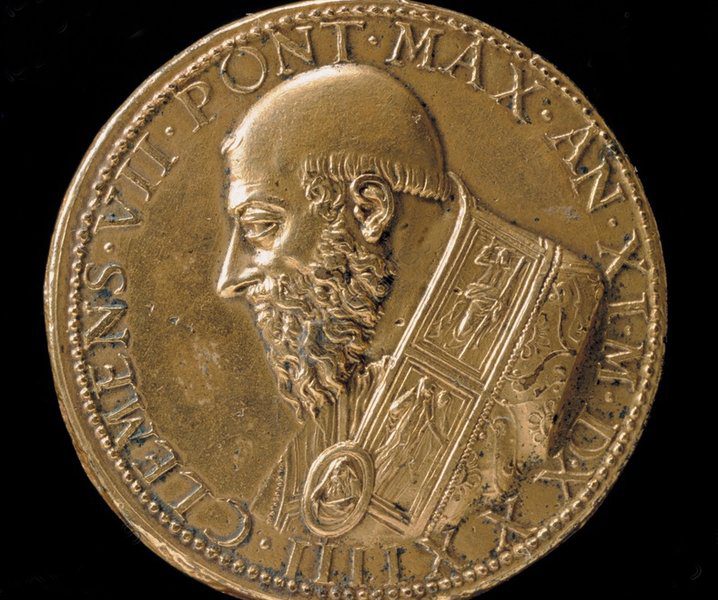

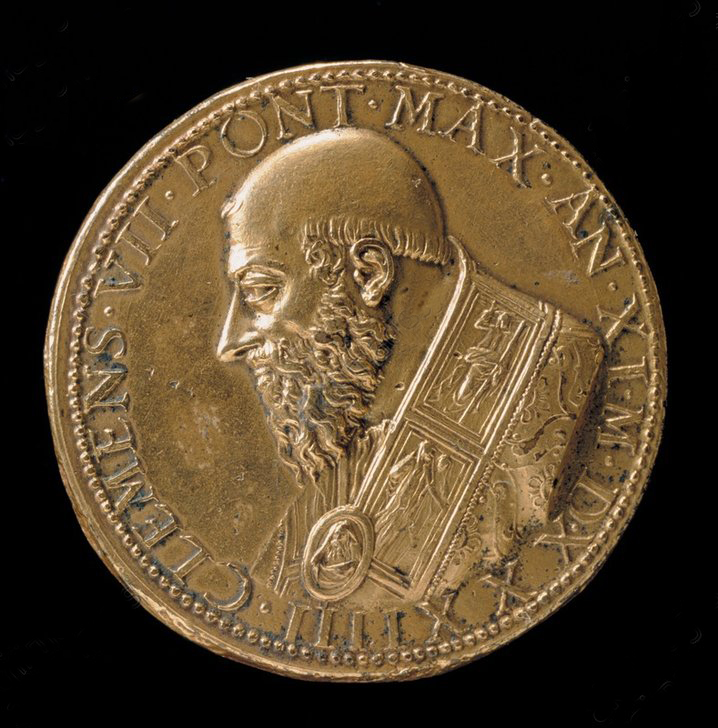

With soft lead sheet as the material for stamping, Bramante’s screw press would not have needed great force in order to produce an even, high-quality impression and to do so rapidly, helping his office to cope with the rising volume of papal documents to be sealed. However, a sufficiently robust screw press had the potential to apply great force, as it could combine the screw’s gearing advantage with leverage, using a long lever to drive the screw. This potential of the screw press to apply massive force was realised in the making of struck medals, with Benvenuto Cellini as its best-known advocate. In his Treatises on Goldsmithing and Sculpture of 1568, Cellini, who had served as mint-master and engraver of dies for hand hammered coins for Pope Clement VII from 1529 to 1534, recalls his adoption of the screw press to strike ‘about one hundred of the medals I made for Pope Clement’ (Cellini, trans. 1898).

The screw press used by Cellini to strike his Clement VII medals must have been capable of great pressure. The Treatises tell us his medals ‘were done in the purest bronze without any casting’ – struck in a hard metal from plain blanks, which had not already been roughly cast into the design of the medal (Cellini, trans. 1898). Cellini explicitly recommends mechanised striking as providing a better quality result than traditional hand hammering methods. More expensive, due to the cost of equipment, but mechanised striking pays back this investment, Cellini writes, with results of finer quality, produced with less effort:

I advise every artist to note well this method of striking with the screw, for, though it be more expensive, the impressions are better, and the dies not so soon wore out. Of the gold and silver medals, I struck many straight off without softening the first: & as for the cost, perhaps after all it only appears greater, for whereas in the method of striking with the screw two turns of the screw will complete the medal, in the method of striking in the coniare [framework] process at least one hundred blows with the stamps are necessary before you get the desired result (Cellini, 1898).

The example of Cellini’s Clement VII medal in Figure 1 gives an idea of the high definition made possible by mechanised striking. Cellini’s observations on the benefits of mechanisation are reiterated by Vasari’s 1550 reference to using the ‘force of screws’ in making die-struck medals, as a preferable alternative to using ‘wedges’ and ‘hammer blows’ – the framework hand striking process (Vasari, trans. 1907 pp 75–76). Vasari viewed the screw press as a technology reserved for the making of prestigious medals in high relief, not necessary for the making of coins and the more basic kind of medal. ‘Coins and other medals in low relief,’ Vasari writes, ‘are stamped without screws, by blows of the hammer struck by hand’ (Vasari, trans. 1907, p 167).

In his Treatises, Cellini gives a detailed account of the construction of a screw press and its advantages over hand striking for the making of medals. He describes how a male iron screw ‘three fingers thick’ with ‘its threads square’ for greater strength is engaged in a female brass screw set in an iron frame. The frame holds the square dies, which are wedged against the frame to prevent them from turning when the screw is applied. A crossbar or lever is attached to the head of the screw, made of a ‘long iron rod or bar, say six cubits in length, so that four men can work at it, and bring their force to play upon your dies and the medal you are striking’ (Cellini, trans. 1898, p 77), which suggests a crossbar about 2.4 metres long (Vitruvius, trans. 1999).[4] Cellini’s screw press must have been a very substantial piece of equipment, containing a lot of metal and costing a lot of money to build, but the benefits of his press outweighed the cost.

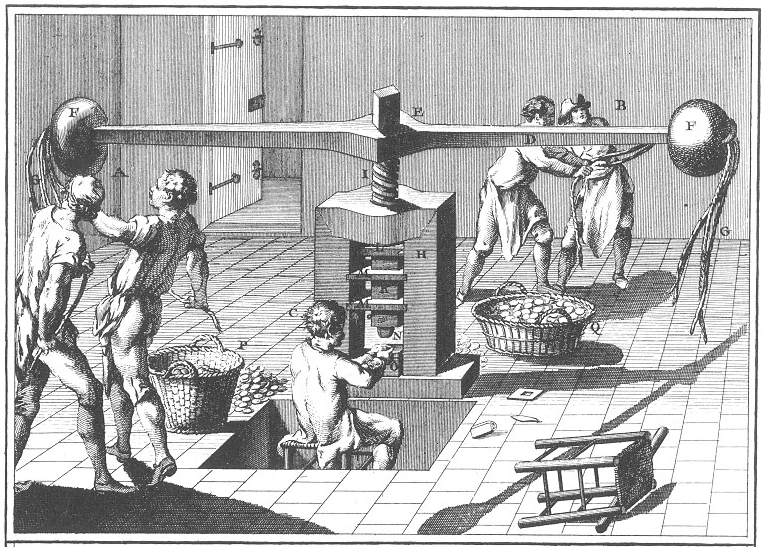

Cellini’s mid-sixteenth century press has all the main characteristics of later screw presses, lacking only weighted balls on the ends of its operating levers. At some point in the second half of the sixteenth century, heavy balls were added to each end of the screw press crossbar, as seen in the eighteenth-century coining press in Figure 2, the effect of which was to add momentum to the leverage of the arms and the gearing advantage of the screw. As also seen in Figure 2, the operators pulled the weighted levers with flexible leads from in front, rather than pushing. This pulling with leads allowing them to gain maximum speed up to the impact of the die and sudden halting of the crossbar, without fearing the broken wrists that might result from pushing hard and coming up against sudden resistance.

Medals then, not coins, were the inspiration for the development of mechanised stamping, as a way of obtaining high quality in a semi-luxury volume product, a quality which could not be delivered in volume by traditional hand-craft methods. Vasari and Cellini both emphasise the use of the screw press for medals only, allocating mere coins to the traditional low-cost, high-speed, hand hammering process.

Use of the screw press eventually replaced hand hammering of coins. Mechanised striking of coins offered the benefits of a higher quality product, less easily forged and more acceptable to users. But due to a combination of conservatism, concern about the cost of machinery, a slower rate of production and moneyer resistance to change, mechanised coin making did not become established across Europe until the second half of the seventeenth century. Mechanisation at the Tower of London Mint was established in 1662, spurred on by the rising problem of coin clipping. The illegal shaving of precious metal from the edges of coins, made easy by the undefined rims of hand hammered coins, could be deterred by mechanisation, which now included the capability for milled and lettered edges, articulated in the phrase decus et tutamen, ‘a decoration and a safeguard’ impressed on the edges of high value coins made at the Tower Mint by the new method and seen again on the edge of the modern pound coin (Cooper, 1988).

Samuel Pepys made a tour of the new coin making machinery at the Tower in 1663. He wasn’t allowed to see the highly secret edge-making equipment, but did see the sheet metal rolling, blank pressing and coin stamping processes, with teams of men spinning the arms of massive screw presses, similar in scale and design to that shown in Figure 3. Pepys noted that the new process was probably more expensive than hand striking and did not save labour, but produced results of higher quality which would be harder to counterfeit:

they say that this way is more charge to the King than the old way, but it is neater, freer from clipping or counterfeiting, the putting of the words upon the edges being not to be done (though counterfeited) without an engine of the charge and noise that no counterfeit will be at or venture upon, and it employs as many men as the old and speedier (Pepys, 1663).

Pepys makes it clear that mechanised stamping of coins was not about saving costs of labour or materials. Due to investment in machinery, mechanised production may have cost more than hand stamping, as Pepys suggests. But as with the mechanised striking of medals, the primary objective was to overcome the limitations of hand-craft methods and achieve a volume product of high quality, rather than maximum volume or lowest cost.

Pepys’ view of mechanised striking was not shared by nineteenth-century and later numismatists influenced by Arts and Crafts thinking, who tended to disparage die-struck or ‘milled’ coins as artistically inferior. Similar complaints were applied to die-struck Renaissance medals. A still-influential scholar of Renaissance medals, G F Hill, speculated in 1920 that:

the artists of the older school must have felt towards the new art of striking medals much as calligraphers and lovers of fine manuscripts must have felt towards printers […] Some of the older artists may have viewed with dismay the base mechanical ease with which, the die once made, the product could be multiplied. […] The best artists of the sixteenth century continued, some of them exclusively, to use the casting process (Hill, 1920).

But as Hill unintentionally implies, many of the best sixteenth-century medallists also used both methods alternately. Their decision on which method to use is likely to have rested on the nature of the commission and the volume to be produced, die-stamping requiring a longer production run to offset the relatively high initial cost of cutting the die, rather than a concern with the hand-craft authenticity of the results (Trusted, 1990).

The Arts and Crafts opposition of industry and craft, which informs still-used twentieth century reference works on medals and coins, is at odds with the pragmatic approach of Cellini and Pepys. They saw no opposition between machinery and craft, only a higher quality if somewhat more expensive product, the quality of which could not be matched by the use of hand-craft methods alone.

The screw press and the manufacture of ornamental metalware

https://dx.doi.org/10.15180/211606/003As use of the screw press for coin making became widely adopted across Europe during the second half of the seventeenth century, the large scale of this activity sucked in the technologies involved and made them more specific to the process. State controls were applied to prevent the proliferation of screw press technology outside the walls of the mint to reduce the threat of counterfeiting, which had the effect of denying access for ornamental metalware manufacture. As in other parts of Europe, English law threatened draconian penalties merely for the unlicenced possession of anything that looked like coin-making equipment. Nathanial and Thomas Morgan were found guilty of high treason and executed in 1698 for counterfeiting and for ‘knowingly hiding, concealing, and keeping a Press for Coining […] without any Authority from our Soveraign lord the King’ (The Old Bailey Proceedings Online, 1698).

However, in England, though mostly not in mainland Europe, technologies originally developed for medal making which had been appropriated for minting were then reapplied to ornamental metalware from the late seventeenth century onwards, without official sanction and on a large scale. By the middle of the eighteenth century, the extensive use of mechanised low-relief die-stamping, particularly in Birmingham, had become a key ingredient in the international success of English metal toyware, as it was known – not children’s toys but small, attractive low relief metalware items such as buttons, the decorative parts of shoe buckles or snuff-box lids, with die-stamped ornamentation which looked like hand chasing.

Nevertheless, the theoretical possibility of prosecution for possession of equipment which could be used to make coins lingered on. In a case of 1753, John Bell is indicted ‘for that he, not being employed in or for the mint in the tower of London, or elsewhere, had in his custody a press for coinage, contrived and resembling the presses for coinage in the tower of London, and this without any lawful authority’ (The Old Bailey Proceedings Online, 1753). Bell is found guilty as charged but judgement is ‘respited’ and there is no punishment, most probably because the court is unable to connect Bell directly with the making of counterfeit coin and judges felt unable to condemn him merely for owning a piece of equipment in common commercial use.

Controls on the use of screw presses outside the state mint were more vigorously applied in France and other parts of mainland Europe until late into the eighteenth century. They also applied to Jean Dassier of Geneva, the best-known member of a die-engraving dynasty, whose remarkable early-eighteenth century die-stamped ornamental metalware was brought to light in numismatist William Eisler’s study of 2005 (Eisler, 2005). Jean Dassier became famous for his medallic work, but began his career with the production of semi-luxury silver goods, stamped in low relief, such as the lids of snuff boxes or watchcases made as flat stampings, then somehow formed into curved cases. The extraordinarily fine quality of Dassier’s die-stamping of ornamental metalware was said by a contemporary to make the same effect as fine hand chasing or chiselling: ‘faisoient le meme effet que les ouvrages cizelés’ (Eisler, 2005, p 16).

Two early-eighteenth century objects in the V&A metalwork collection give an indication of the quality of Dassier’s die-stamped luxury goods. A Dassier watchcase and a plaque, possibly intended as the lid of a box, look like high-quality chasing but were certainly stamped, using the same die.[5] The medallion of William III at the centre of the design shows obvious associations with the making of coins and medals, but clearly the plaque in Figure 3 is something else, a decorative metalware component, and the watchcase in Figure 4, which still contains its watch, is obviously not a medal. Eisler’s work makes it clear that Dassier’s watchcases were stamped as flat objects in low relief, like uniface medals and like the plaque in Figure 3, then shaped into watchcases by a process still unidentified, possibly involving the careful hand-tool pressing of the flat stamping over a wood or lead former, in such a way as to avoid flattening and spoiling the stamped design.

Unlike the Birmingham ornamental metalware trades, the Dassiers’ access to die-stamping technology was firmly controlled by the state. In 1706, when the mint of the Genevan Republic was transitioning from hand stamping to use of the screw press, the Dassier family offered to finance the purchase of a screw press for use by the mint, in return for permission to access that press from time to time and use it for their own purposes. A huge screw press or balancier, weighing perhaps two tons, was built in Nuremberg and installed at the mint in 1708. However, though financed by the Dassiers, the machine remained firmly under state control and could only be used for Dassier metalware production with express permission from the state on each occasion (Eisler, 2005, p 19).

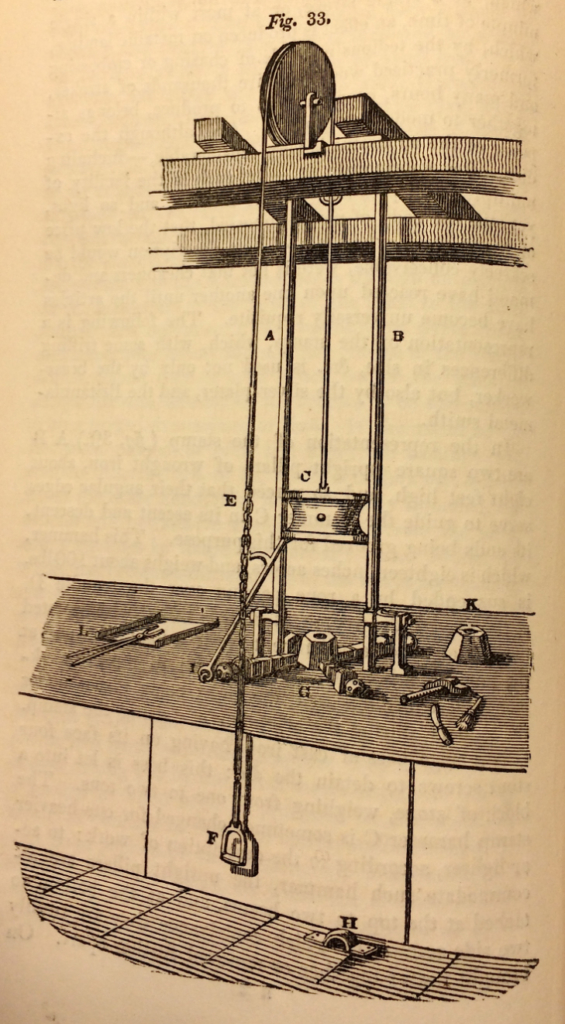

The drop stamp

https://dx.doi.org/10.15180/211606/004The drop stamp, as its name suggests, relies on gravity not leverage to apply force. A heavy hammer is held captive in a frame, like a guillotine blade. An steel intaglio die is fixed rigidly at the base of the stamp. The hammer has a cameo force of some kind attached to its face, which can be a cameo version of the intaglio die made by taking a soft metal alloy casting from that die, or it can be a more approximate shape, designed only to press the metal into the broad outline of the die to start with, before a more highly defined force is used at a later stage of stamping into a deep die. This is different from the paired steel intaglio and cameo dies used in making the E-Type bonnet, where the combination of the squeezing action and enormous force of a hydraulic press the size of a small house are able to persuade sheet metal into the required shape in a single continuous action.

Sheet metal is placed on the intaglio die at the base of the drop stamp; hammer and force are raised to a height and then allowed to drop. The pressure exerted can be immense, with a long drop and a heavy hammer, but can be very easily controlled, ranging from a sharp tap to a massive blow simply by varying the drop height. This pressure is always applied in a dead straight line, with no possibility of sideways twist as might be the case with a screw press.

This is how Tony Evans, the former owner-manager of J W Evans & Sons, stampers and piercers of Birmingham, established in 1881 and now a preserved industrial site (English Heritage, 2014), described the difference in the effect of a nineteenth-century drop stamp compared to a fly press, a bench-mounted screw press:

If […] instead of stamping a wine label in a drop stamp you were to use a fly press, you’d be very hard pushed to generate enough energy, even with the big weighted balls which you can put on the top of the arms – with a good swing on the arms of the press, [the weighed balls] can add to the force being applied below. A press squeezes the metal where the drop stamp slams it with a different type of force – it’s happening a lot faster – an awful lot of energy is building up – the sudden shock of this thing descending from six to ten feet in the air and suddenly coming to a dead halt on a very solid base – there’s no give in the base whatsoever, that’s absolutely vital – then all that energy is suddenly having to go somewhere and it’s deforming the metal sandwiched between the force and the die.[6]

The origins of the drop stamp are unclear, but it appears to have been adopted and developed by the English ornamental metalware trades in the first half of the eighteenth century, particularly for the simultaneous shaping and decoration of buttons. More or less flat products such as box lids could be successfully stamped with a screw press, but something like a button with a domed shape is likely to have been easier to make by using the higher and very linear pressure provided by the drop stamp. Button dies carried both the overall shape and the detailed decoration of the button, designed to emulate hand chasing. With the help of a drop stamp to push metal into the deepest, detailed parts of an intaglio button die, the button could be both formed and decorated at the same time, possibly with a single blow.

Also, it is likely that the drop stamp was less laborious and faster in operation than the screw press or even its bench-mounted equivalent, the fly press. Just one man would operate a drop stamp, whereas a large floor-mounted screw press typically required teams of men to operate. And the interval between blows could be shorter with a drop stamp, as raising the hammer took less time and effort than rewinding the screw press back to its starting position.

There is clear evidence for English use of the drop stamp in button making as early as 1749, when a Swedish investigative tourist, Samuel Schroeder, described how a drop stamp was used in Birmingham:

The aforementioned small blanks which are cast are then stamped in steel moulds to the shape of buttons as required. The second mould is concave and engraved with the pattern, the upper mould is convex and is fixed in a sufficiently large iron weight, which is hoisted up with a block and by its own weight it moulds the blanks to buttons when it falls down. The weight passes between two posts and in this way it falls straight. A man hoists the weight, holding the rope in his hand and with his foot in a piece of iron resembling a stirrup at the end of the rope (Schroeder, 1989).

There is a similar first-hand account of drop stamping to make buttons written just over 20 years later by a visitor of 1770 to Boulton’s Soho manufactory (Goodison, 2002).[7] A French investigative tourist, Francois La Rochefoucauld, described drop stamping to make buttons in Sheffield in 1785 in very similar terms to those of Samuel Schroeder:

The stamp is made up of two pieces; one is a little anvil on which the design of the button is hollowed out; the other is the same design embossed so that they fit together exactly. The embossed piece is fixed on the underside of a fairly heavy iron weight: this kind of ‘drop-press’ is raised between two perpendicular wooden posts by means of a cord passing over a pulley and attached to a stirrup which a man works with his right foot. The man places the roundel of plate on the mould, lifts the drop-press and lets it fall so that the button is imprinted with the design (Scarfe, 1995).

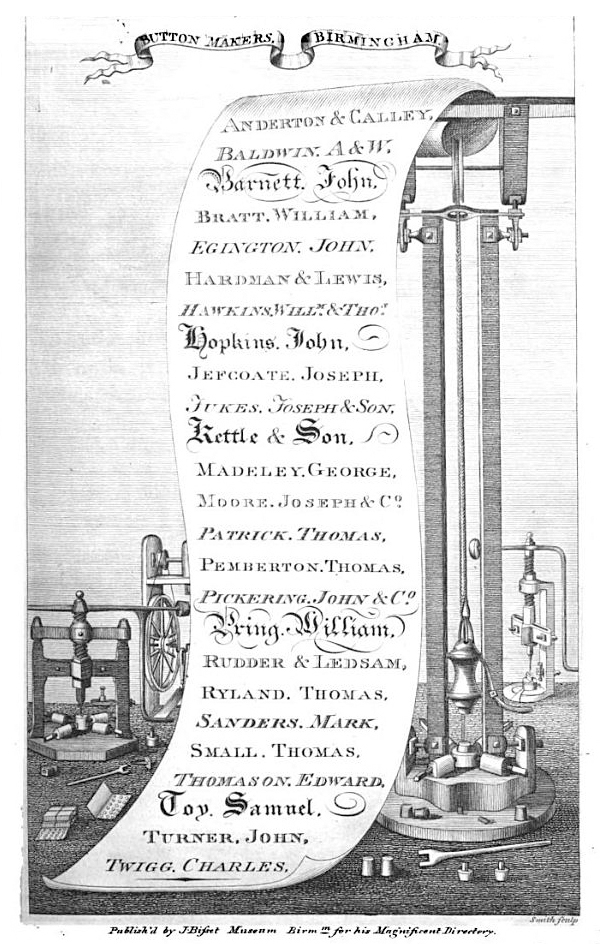

An engraving of 1808 (Figure 5) portrays a drop stamp as an essential machine for button making.

The drop stamp described by Schroeder and other eighteenth-century tourists is likely to be an innovation arising entirely from the ornamental metalware trades, developed (if not invented) in England. Development of the drop stamp in mainland Europe would have been prevented by state controls on the use of stamping machinery.

Histories of coin making have no place for the drop stamp. Eighteenth-century coin making production technology remained focused on the screw press, culminating in Mathew Boulton’s introduction of a steam-powered screw press in the 1790s, complete with automated placing of blanks and removal of finished coins. The drop stamp was developed by the ornamental metalware trades for the manufacture of luxury and semi-luxury products and had nothing to do with coin making.

The success of mid-eighteenth century English mechanised stamping in low relief

https://dx.doi.org/10.15180/211606/005Although few English stamped ornamental objects made before 1760 have survived, there is extensive documentary evidence of the scale and success of this industry, and the key role played by mechanised stamping technology.

The Birmingham manufacturers John Taylor and Samuel Garbett gave evidence to a 1759 parliamentary committee that 20,000 workers were employed in the toy trades in and around Birmingham, the value of the ornamental part of the trade being estimated at £600,000 per year, £500,000 of that total value being exports.[8] Their evidence also noted that ‘Many of the Goods are made by the help of Machines or Engines, invented by the people of Birmingham, which lessens the manual Labour, and enables Boys to do Mens Work, and sometimes more’.

The role of machines or engines for low-relief stamping is made very specific in other contemporary texts. Referring probably to the use of a drop stamp, as with the Samuel Shroeder journal entry, Josiah Tucker remarked in 1755 that:

When a man stamps on a metal Button by means of an Engine, a Child stands by him to place the button in readiness to receive the Stamp, and to remove it when received and then to place another […] And hence it is that the bijoux d’Angleterre, or the Birmingham Toys are rendered so exceeding cheap as to astonish all Europe (Tucker, 1755).

Setting out to explain the ‘great rise’ of the Birmingham hardware trades in the 50 years leading up to 1766, Lord Shelburne also found that mechanised stamping and division of labour were critical ingredients. In his view, Birmingham’s success was:

owing to two things, first the discovery of mixed metal so mollient or ductile as easily to suffer stamping, the consequence of which is they do buttons, buckles, toys, and everything in the hardware way by stamping machines which were before obliged to be performed by human labour (Fitzmaurice, 1912).

Both Tucker and Shelburne stress the cost reducing effect of mechanised stamping, speeding up production and reducing the strength and skill required, so that boys could be used alongside or instead of men, together with the use of highly divided labour. Low-relief stamping was rapid by comparison to hand chasing and steps in the production process were carried out more quickly by workers who specialised only in one step. But there is also an implied argument about quality. In a semi-luxury volume production context, die-stamping provided a better quality result than hastily executed hand-craft alternatives. Europe was ‘astonished’ that buttons or other goods of such high quality could be made for such low prices, not astonished by price alone. Shelburne’s 1766 commentary elaborates on this, noting the high quality of a stamped metal button in cleverly imitating the effect of a woven textile:

upon the whole they have reduced the price so low that the small matter of gold on a button makes the chief expense of it, being as three to one including all other materials and manufacture. However, they have lately discovered a method of washing them with aquafortis, which gives the colour of gold, and are come to stamp them so well that ‘tis scarce possible at any distance to distinguish them from a thread button.

A revealing newspaper article of 1761 stresses the quality of die-stamped toys and links that quality to export success:

several curious and useful productions are afforded at very moderate prices, by means of this ingenious invention of dies, which strike excellent pieces of workmanship almost instantaneously. Thus it is that sword-hilts, watch-chains, buttons, snuff boxes, dial-plates, and many other valuable branches of manufacture are executed with so much exactness and facility, as enables us to spread our commerce in those articles to every part of the world.[9]

So while volume and low production cost were critical for the success of English mid-eighteenth century toyware, it was the quality of finish made possible by mechanised die-stamping that ensured the international success of this trade. And though the price of English toyware was lower than hand-crafted alternatives, these products remained luxury or semi-luxury objects: sword-hilts, watch-chains and decorated show-off buttons, which might be made of copper alloy plated with gold, or the new fused silver plate from Sheffield. The semi-luxury market led the development of mid-eighteenth century metalware production technology.

Sheffield plate and mechanised drop stamping in high relief

https://dx.doi.org/10.15180/211606/006Early to mid-eighteenth century drop stamping to make anything larger than a button was constrained by the size and quality of the dies that could be made. Before cast steel became more available in the 1750s, following Benjamin Huntsman’s discoveries in Sheffield in the 1740s,[10] large steel die blanks were not feasible. A large die blank made of traditional shear steel, blister steel bars forged into a block, would have been hard to make and would have been suffused with variations in structure, therefore difficult to carve smoothly and more likely to break down in use.

With knowledge of the drop stamp gained through local production of metal buttons and enabled by access to improved Sheffield cast steel die blanks, at some point in the 1750s the Sheffield plated trade developed drop stamping in high relief, as a way of making Sheffield silver-plated sheet look like cast silver.

The material which became known as Sheffield plate had been discovered there in about 1742 (Crosskey, 2011). This new material involved the fusing together of a relatively thick block of copper with a much thinner block of silver in a furnace. The cooled block would then be rolled into sheets. Because silver and copper expand at the same rate under pressure, the end result of the rolling process was a laminar sheet consisting of a layer of copper and a thinner layer of silver, corresponding to the proportion of copper to silver in the metal blocks fused together at the outset.

Sheffield plate was initially used to make knife and fork handles, buttons, buckle parts and other small toyware objects made to look like solid silver, stamped in low relief. Somewhere between 1750 and 1760, the Sheffield plated trade developed new high relief drop stamping techniques to simultaneously shape and decorate larger components, possibly using taller stamps with a longer drop and heavier hammers than those used in making toyware, with larger dies made possible by the use of Sheffield crucible steel. As a laminar material, Sheffield plate could not be cast, but the new high relief drop stamping techniques allowed the Sheffield plated trade to imitate the appearance of expensive cast silver candlesticks with plated components stamped in high relief, which were then soldered together to create the appearance of a solid object.

At the same Sheffield manufactory where Francois La Rochefoucauld witnessed button making with a drop stamp in 1785, he also observed high relief drop stamping in progress for the making of tableware:

The same manufacturer also made plate in great quantities. The processes are not very different…the pattern is pressed in with the drop-press…the only difference is the greater intricacy of the plate, requiring greater care and workmen more skilled.

Greater care and more skill is certainly needed for high relief drop stamping. Sheffield plate candlesticks made by this method involved eleven or more separately stamped components to make a complete candlestick, each of which would be stamped a number of times to reach its final form, perhaps in several stages, not made with a single massive blow (Crosskey, 2011, pp 35–36). Deep stampings have to be shaped gradually, with multiple blows and annealing at intervals, to avoid creasing and puckering the metal. This is a key principle for high relief drop stamping and separates it from earlier eighteenth-century low relief stamping, such as the high-speed button making operation described by Josiah Tucker.

The stamped candlestick components would be assembled and very skilfully soldered together, leaving almost no visible sign of the solder line. Excess solder could not be filed away, for fear of cutting through the silver layer and exposing the copper beneath.

Despite the labour-intensive nature of the process, Sheffield plated candlesticks made by mechanised drop stamping in high relief, which matched or exceeded the visual impact of cast silver equivalents, could be sold at around one sixth of the price. This was because Sheffield plate sheet, made mainly of copper but with a skin of sterling silver, was so much less expensive than cast solid silver (Clifford, 1999); particularly so in the eighteenth century, when the value of silver bullion was a great deal higher in real terms than it is today. The same high relief drop stamping technology was soon applied in Sheffield and then in Birmingham to silver production, allowing thin silver sheet to be used in place of heavy and expensive cast silver.

Though Sheffield plated goods cost less than silver equivalents, which made them affordable for the expanding middle class, Sheffield plate items made by high relief drop stamping still counted as luxury goods. Items such as the Boulton and Fothergill candlesticks (Figure 7) were bought by aristocrats and other traditional customers for silver, as well as the middling sort. Gordon Crosskey, writing in what is now the standard reference work on the history of Sheffield plate, maintains that:

…at least as far as the 18th century was concerned, the word plated did not carry the pejorative connotation that it has in later times. Customers, whether the Prince of Wales, the Duke of Hamilton or the country curate, were equally happy to buy their dish covers, tea urns or coffee pots in plated metal. Such articles, although cheaper than their silver counterparts, were not regarded as aesthetically inferior or any less beautiful (Crosskey, 2011).

The high relief stamping process relied on the stamper’s ability to control pressure. The stamper can drop the hammer from lower heights in order to slowly coax sheet metal into a deep die. Tony Evans described in interview the gradual nature of the high relief stamping process, made possible by varying the height of the drop:

So you’ve got to determine just how far you can go, the first blow might have to be just sufficiently hard to drop [the metal] say less than a centimetre into a die. You’ve got to be guided by the way the edge is crinkling up – you can see how the edge of the metal wants to fold up as it’s distorted, it all wants to crease up. Round the edge of the stamping if those creases get too deep then eventually those creases will get drawn down into the stamping. If it was say a salt pot then you’d see these folded lines, folded metal going down the sides of the finished article. So you need to go down just sufficient, and you can only do it by trial and error, to draft the metal into the die just far enough so you don’t annoy the metal too much, and then stop, anneal it so that you’ve got the ductility back into the metal and then go down with a slightly deeper force.[11]

But when the stamper does use the full height of the drop, perhaps to impress the last fine details into a nearly finished stamping, the pressure exerted by the fall of a 50lb or heavier hammer on to a rock-solid stamp bed is immense.

The Pickering patent

https://dx.doi.org/10.15180/211606/007The invention of stamping in high relief with a drop stamp is often mistakenly attributed to a patent of 1769, No. 920, granted to John Pickering, a gilt toy maker of London, for ‘a New Method of Performing that kind of Work commonly called Chasing, for the Working in Gold, Silver, Brass, Tin and other Metals of various Things…by a Machine consisting of an Oblong Square Frame with Two Rods, in which a Moving Forcer is worked upon a Striking Block, with a Die fixed thereon formed for each respective Purpose’.[12]

The mistaken emphasis on the Pickering patent seems to emanate from Henry Hamilton’s history of the brass industry, written in the 1920s and still the main reference work on the topic. Hamilton maintained that the introduction of the stamped brass foundry trade to Birmingham ‘is usually associated with an invention by one John Pickering’. Hamilton concludes that Pickering’s 1769 patent ‘was the idea which was at the root of the whole stamped brass foundry trade’, and that this trade developed and became specialised so fast that ‘even in 1770, there were various stampers, die sinkers, stamp and press makers and button stampers in Birmingham’ (Hamilton, 1926). Fast indeed, for an entire community of specialists and supporting infrastructure to have developed in a year.

Many later writers on the history of ornamental metalware seem to have taken their cue from Hamilton or from the Samuel Timmins, Hamilton’s likely nineteenth-century source (Aitken, 1866), even leading contemporary historians such as Maxine Berg, who wrote that:

The stamped brass foundry trade, using sheet metal, die and hammer, was introduced by the London toy maker John Pickering and spread so rapidly in Birmingham that by 1770 the town housed stampers, die-sinkers, stamp and press makers, and buttons stampers (Berg, 1985).

But by 1769, use of the drop stamp for the making of components in high relief for candlesticks and other products had long been established in the Sheffield plated and silver trades and, following the example of Sheffield, was also well underway at Matthew Boulton’s Soho manufactory in Birmingham. The Birmingham Assay Office collection has a pair of Boulton and Fothergill stamped silver candlesticks with hallmarks for the Chester assay year 1768–69, a design in the French taste also made in Sheffield plate with the same dies, as can be seen from a plated pair recently sold at auction (Figure 8). Clearly the foundations for this Birmingham product were laid far in advance of Pickering’s 1769 patent.

Following its mid-eighteenth century development by the Sheffield plated and silver trade, drop stamping in high relief became disseminated to brass and other ornamental metalware trades, in Sheffield and in Birmingham. A detailed description of high relief drop stamping appeared in an 1834 volume of Lardner’s Cabinet Cyclopadia, written by Sheffield author John Holland (Holland, 1834). The description is focused on brassware, being the metalware trade with far and away the highest volume of stamped output by 1834, but Holland includes the stamping of silver plate (still fused Sheffield plate at this date), and Britannia metal, a malleable pewter alloy used to imitate Sheffield plate and silver designs. A range of ornamental metalware trades were drawing on a common core of high relief drop stamping machinery and methods:

The stamp, which, with some trifling differences in size, &c. is used not only by the brass-worker, but also by the silver-plater, and the Britannia-metal smith (Holland, 1834).

On the evidence of surviving drop stamped Sheffield plate and silver objects produced from the early 1760s onwards, which match or exceed the quality of any later die-stamped work, it is reasonable to suppose that high relief drop stamping reached the limits of its development in the plated and silver trades of the 1760s, when the design of the process stabilised and became disseminated to other metalware trades, but changed little thereafter. The processes used to make a drop stamped Sheffield plate candlestick base in the 1760s would have been more or less the same as those used to make an ornamental brass curtain hook as described in Lardner’s Cyclopaedia in the 1830s, or a reproduction Georgian candlestick in silver at J W Evans in the 1990s.

As with the sixteenth century Italian Renaissance development of the screw press for the striking of medals, the eighteenth century Sheffield development of high relief drop stamping was driven by a need to find a way of producing high-quality luxury products for a volume market, and to avoid the use of casting. For the commercially-driven Sheffield plated and silver trades, lower selling price was the key to volume sales, and this was achieved not by cutting manufacturing costs but by the use of less expensive sheet material. This use of sheet material was made possible by a combination of mechanised high relief drop stamping techniques, requiring great operator skill, and traditional hand-craft skills in soldering and assembly. Overall, the high relief drop stamping manufacturing process almost certainly involved higher labour costs than with traditional silver casting. But the savings arising from use of Sheffield plate or thin silver sheet ensured that the finished object could sell at less than the high price of cast silver, while matching or exceeding its visual impact. Mechanised drop stamping in high relief was the development in production technology which made this possible, by providing a method of both decorating and shaping sizeable metalware components at the same time.

Nineteenth century and later development of die-stamping

https://dx.doi.org/10.15180/211606/008As the range of manufactured goods expanded in the nineteenth and twentieth centuries, with the emergence of new industries based on the making of mechanical components in high volume, for products such as typewriters, bicycles and motor cars, the role of luxury goods as a driver for the development of metalware production technology declined. New forms of die-stamping were developed, such as the ‘deep drawing’ of cylindrical shapes, driven by the making of artillery shell cartridges, motor car parts or tin cans, rather than luxury goods.[13]

‘Deep drawing’, where the depth of the stamping is greater than the diameter, is associated with the mid-nineteenth century introduction of hydraulic and other power-driven presses, with some form of double action and able to apply many times the pressure of the gravity-powered drop stamp. Part of the action of the deep drawing stamping machine grips the excess, the flange of the object to be shaped, while another part does the stamping. Gripping the flange in this way prevents the metal from puckering and creasing as it is forced down into the deep die.

But the legacy of die-stamping development for ornamental metalware can still be seen in modern production methods. The fundamental idea behind the pressing of the E-Type Jaguar car bonnet, and all modern metalware car body components, can be traced back to the high relief drop stamping of the eighteenth-century Sheffield plated and silver trades.

Conclusion

https://dx.doi.org/10.15180/211606/009The early modern history of ornamental metalware provides a compelling example of how the making of luxury and semi-luxury goods can sometimes drive the development of mechanised production technology. Mechanised stamping with dies, using a screw press, was initially developed for the making of High Renaissance portrait medals and was extended to other low relief ornamental metalware, such as the extraordinary early-eighteenth century work of Jean Dassier, who produced superb but more or less flat die-stamped work with a screw press, which then had to be shaped into usable objects such as watchcases in a secondary process.

Mechanised stamping took another step with the English eighteenth-century development of the drop stamp, which provided high pressure with greater convenience and was used initially to make buttons and other semi-luxury ornamental metalware objects in low relief.

The full potential of the drop stamp was realised by the Sheffield plated trade, which developed drop stamping in high relief in order to emulate the appearance of cast silver candlesticks, by stamping plated sheet into high relief components which were then soldered together to create the appearance of a solid cast silver candlestick. Though sold at a much lower price, the stamped plated and then silver candlestick could match or exceed the quality of cast silver. Stamped candlesticks competed so effectively in the luxury market that they drove cast silver candlesticks out of production: stamping became the standard way of making a silver candlestick.[14] Products such as the Boulton and Fothergill stamped candlesticks (see Figure 7) offered a medallic level of detail and precision which met the late-eighteenth century appetite for neoclassical decoration in ways that would have been difficult or impossible with traditional hand-craft casting methods.

Arguably, the Sheffield invention of drop stamping in high relief is the critical transition from stamping to make medals and stamping or pressing to make three-dimensional components for Jaguar E-Type and other metal car bodies, including components such as the E-Type car bonnet – as difficult or impossible to make by hand-craft methods as the candlesticks in Figure 7. And the eighteenth-century Sheffield idea of constructing candlesticks by soldering stamped components together has a remarkable resonance with the twentieth-century development of the monocoque or unibody car, with pressed components welded together to create the appearance of a seamless whole.

Tags

Footnotes

https://www.jaguar.co.uk/about-jaguar/jaguar-classic/authentic-cars/classic-continuations/index.html (accessed 5 October 2021) Back to text