Preserving skills and knowledge in heritage machinery operations

Article DOI: https://dx.doi.org/10.15180/211602

Abstract

This article details an approach to knowledge capture on a collection of working textile machinery at the Science and Industry Museum. The machinery collection dates between 1880 and 1955 and the knowledge capture process outlined in the case study was prompted by the retirement announcement of the last machine operator on staff with first-hand experience of the textile industry.

Heritage machinery demonstrations provide a unique opportunity for visitors to museums to experience the sights, smells and sounds of Britain’s industrial past. However, with many of the operating roles in the sector being staffed by an ageing population, heritage machinery demonstrations are at risk of substantial knowledge loss over the coming years. Without intervention, many of the tacit skills and knowledge that the operators hold will be lost, along with the opportunity for the public to learn from and experience the machinery first-hand.

The method outlined in this article includes a review of existing documentation, operation recording and interrogation of results, comparison and discussion with stakeholders, and production of documentation and resources. The results of this process included a set of documents that reflected both modern health and safety and conservation and collections care guidelines, as well as cross-media resources that can be used as a future training aid. Though the case study detailed here features textile machinery, it is applicable across many strands of heritage machinery and could provide a useful tool for similar ‘at-risk’ machinery operations in museums and other cultural institutions.

Keywords

craft science, heritage machinery, industrial heritage, industrial skill, knowledge loss, machine operation, practice-led research, skills, tacit skills

Introduction

https://dx.doi.org/10.15180/Museum and heritage site visits provide a unique opportunity for visitors to engage first-hand with the smells, sounds and sights of Britain’s industrial past. By preserving and exhibiting historic industrial machinery, these institutions allow visitors to connect with the lives of historical operators. Nowhere is this felt more strongly than through live demonstrations of historic machinery in action. Core to the Science Museum Group’s vision and strategy for engaging the public, Inspiring Futures (Science Museum Group, 2020), are a set of values that echo the opportunities for engagement available through demonstrating live machinery. Seeing the machinery brought to life, with its thunderous noises and mesmerising movements plays into the Group’s values of revealing wonder and igniting curiosity – sparking questions about the machines, what they were for, how they worked and what was it like to work with them. Through engaging conversations with operators who have real-life experience of the human-machine relationship, the museums can share authentic stories about the humanity behind the machines and the lasting impact they have had on an individual and global scale, making the machines relatable and allowing the visitors to see themselves as part of the story. Outside of the Science Museum Group, museums and heritage sites more widely contribute to the mission to close the science, technology, engineering and maths (STEM) skills gap. By making these experiences accessible to all, these institutions aim to inspire the public to become the next generation of technicians and engineers.

Knowledge loss across various fields within the cultural sector has been highlighted as a significant risk area, with the Museums Association publishing a toolkit based on its five-year Monument Fellowship programme (Museums Association, 2011). With many of the machine operating roles in these heritage institutions being staffed by an ageing population of volunteers, the loss of skilled operators is a major issue facing the museum and heritage sector. Without intervention, the tacit skills and knowledge that the operators hold will be lost, along with the opportunity for the public to learn from and experience working historic machinery. Eventually, this may lead to the suspension of live demonstrations, and a rich mode of visitor engagement would be lost. Human stories related to machine working can be interpreted through static objects such as tools, as explored in the National Museums Scotland ReINVENT project (Ross, 2013); this can help fill in the gaps retrospectively about the eccentricities of industrial machines and the operators that ran them, if they are no longer operable, though this provides visitors with a very different experience from watching heritage machinery operated first-hand. Historic England recognises skills loss in machine operating as a major risk to the heritage sector over the coming years and have outlined a want to develop and expand a training offer in operational and technical skills, including maintenance, repair and operation of historic machinery, in their 2021 consultation draft Industrial Heritage Strategy (Historic England, 2021). Some cultural institutions are now working on projects to re-invest in the skills of heritage machine operators and bring in early career professionals to add to the talent pool, through apprenticeships in heritage skills and work experience opportunities often supported by funding bodies such as National Lottery Heritage Fund. Programmes for supporting the continuation of heritage textiles skills have taken place at Knockando Wool Mill (National Lottery Heritage Fund, 2009), Whitchurch Silk Mill (The Weave Shed, 2019) and New Lanark Industrial Community (Ross, 2013), though it is worth noting that these examples all produce artisanal products for sale at premium prices, giving them further incentive to keep the craft industrial skills alive. Unfortunately, it is not common for heritage sites to publish their methods of skills capture and preservation.

A full and complete transfer of knowledge from one generation of operators to another can be difficult to achieve for three key reasons: staff turnover, institutional culture, and lack of formalised process for knowledge sharing. High staff turnover in technical positions in cultural institutions can be due to lack of progression opportunities and this, combined with either generally low wage or only volunteering roles available, also makes the field less attractive for early career professionals. Where staff do stay longer it is generally people towards the end of their career or semi-retired who may be able to afford to live on a lower wage or volunteer. Staff close to retirement may bring many years of experience with them to a role but will not stay long enough to reduce the amount of turnover and potential risk of knowledge loss without any early career staff to pass the knowledge on to. Where technicians have worked in traditional industries prior to joining a museum or other heritage site, institutional culture inherited from previous roles may persist. Since the 1960s, many jobs that included skilled manual labour in the UK have been under threat of redundancy due to the closing of factories as many manufacturing jobs move abroad. As such, technicians who have worked in the field for a long time may feel anxiety around job security. Anecdotally, this can manifest in some skilled technicians as being hesitant to pass their knowledge on for fear of being replaced, and thus much knowledge has not been recorded. When knowledge is shared, it is often done informally and orally. This may also be influenced by computer illiteracy in older generations of technicians. This can lead to a wide variation in personal techniques and approaches, some of which differ significantly from established safe or approved operational practices of the machinery, or from written historical records. Even where there is a desire to share and preserve knowledge, many operators and technicians struggle to communicate and record the nuances of operation effectively, since this often relies on tacit or practical skills that have been built up through years of experience (Juravich, 2017). Tacit skills have been the subject of discussion across many areas of work from the interpretation of static objects through machine tools (Boon, et al, 2017), craft-led production (Margetts, 2011), to the similarities in skills across disciplines, including those of a master tailor and taxidermist (Kneebone, 2020). The tacit skills held by technicians and operators are best demonstrated when considering the working machine as an extension of the body and thus the senses of the worker (Ellis, 2015), (Margetts, 2011), (Polanyi, 1962, cited in Seiler, et al, 2021). Many of the skills used in machinery operations require additional senses to be used, in particular those that connect the mind and body sensations, such as proprioception (body awareness), thermoception (the sensation of – or absence of – heat), and equilibrioception (balance in relation to motion). For example, it is difficult to quantify the technique required to tighten a stubborn valve, how to diagnose mechanical faults by sound (Staubermann, 2010), or the rhythm and precise timing required to stop a machine at the correct point in its operating cycle. Issues in articulating craft skill, including industrial craft skill (Penny and Fisher, 2021) when operating machinery, can be explored using practice-led questioning techniques (Groth, et al, 2015) to help build a truer reflection of the operator’s experience. Historically, written information has been relied upon to be the source of information for working with machinery. However, given that many operational procedures involve using the body and mind as part of the machine it is often the case that functions are bound by spatial perception and thus are hard to capture in written form and translate better by demonstrating an action in person (Jönsson, 2021). This is also highlighted in the Museums Association Toolkit, where expert-led classes were used to demonstrate tactile- and spatially-affected procedures (Museums Association, 2011), and was demonstrated in both the Scottish Transport and Industrial Collections Knowledge Network’s ReINVENT project where a historic hand loom was operated (Ross, 2013) and through simulated re-enactments of surgical operations with expert retired surgeons who could verbalise their motions to trainees and access ‘institutional memory of collaborative skills’ (Kneebone & Woods, 2012).

Through a case study from the Science and Industry Museum, this article seeks to explore solutions to these issues and to propose a method for knowledge capture that is suitable across a range of operational heritage machinery. The following case study is situated in existing wider theory associated with the study of tacit skills and knowledge, covered extensively in other literature – for example, Staubermann, 2010.

Background

https://dx.doi.org/10.15180/211602/002The Textiles Gallery at the Science and Industry Museum tells the story of Manchester’s historic cotton industry, and its role in creating Manchester as the original shock city of the industrial revolution. It is one of the oldest and best loved galleries and is core to the narrative and purpose of the Museum, revealing Manchester’s industrial past. At its heart the Textiles Gallery features 15 historic, working textile machines ranging in date from 1880 to 1955. It is the only place in the world where visitors can stand in one spot and see the full process of cotton fabric production demonstrated; from the initial breaking of the bales, through the carding and spinning processes, and finally weaving into cloth on a loom. Other than the addition of an electric motor to power the belt drives no other modern adaptations have been made, in alignment with the Science Museum Group’s Conservation Policy on operating objects (Science Museum Group, 2018).

This group of historic textile machines has been operating at the Museum since the gallery first opened in 1997. The operation of the heritage machinery has historically been overseen by skilled operators with prior first-hand personal experience of working in Greater Manchester’s textiles industry. With textiles production shifting away from the UK over time, the pool of skilled technicians able to carry out this work has dwindled. When the last machine operator with first-hand experience in the textile industry announced their retirement, the Museum initiated a knowledge transfer exercise to ensure operational knowledge was not lost.

The operator had 28 years of previous experience working in modern textile mills in Greater Manchester prior to joining the Museum and had worked with the Museum’s collection for a further 21 years. Through her many years of service, the operator shared her knowledge with and trained numerous colleagues on the various operating procedures of the textile machinery, embellishing these with tips and tricks for ensuring a smooth operation. However, this training, whilst detailed and diligent, was delivered in person and not recorded. This was due to a combination of lack of oversight from management, specific challenges around computer literacy of the operator and an unfortunately false belief that someone else would retain the information passed on verbally and become the new holder of the knowledge. This style of information handover was attempted a number of times previously but was unsuccessful as former trainees would leave the organisation due to lack of promotion opportunities and competitive pay. An attempt was made to remedy the lack of oversight by creating a new line-manager role with specific machinery management responsibilities. However, this role quickly became overstretched due to competing priorities as the manager was also responsible for much of the wider Learning programme, and thus the operational knowledge loss surrounding the textile machinery continued to pose a risk to the Museum’s visitor offer.

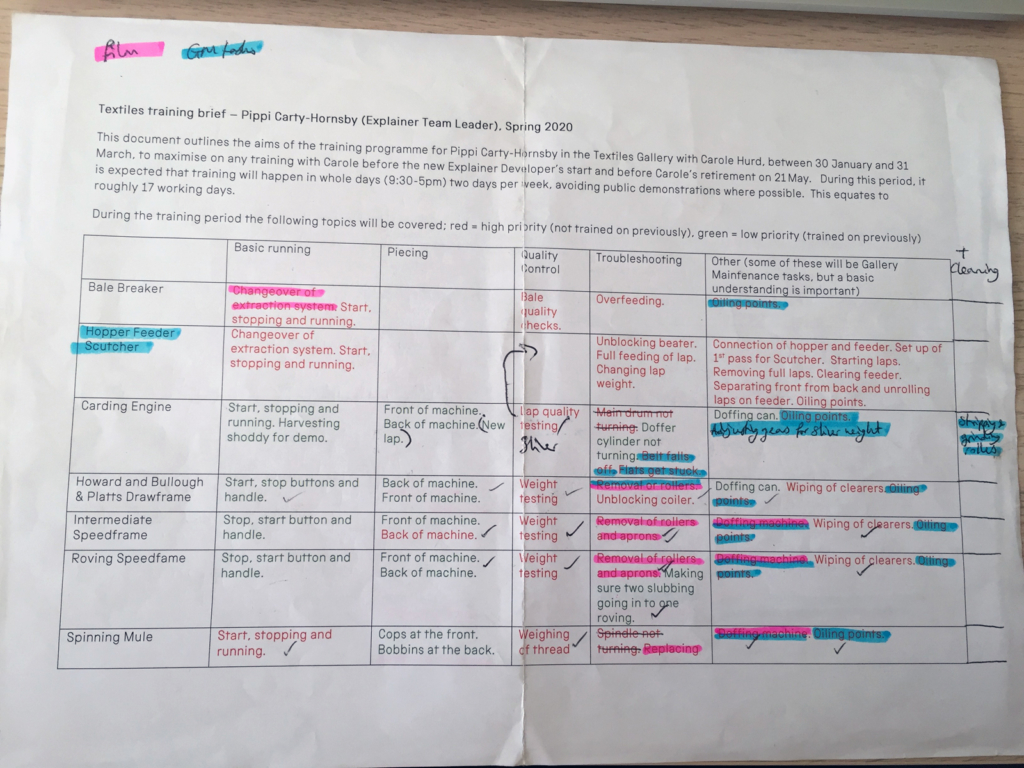

Although the modern documentation for the machinery (including manuals produced in 2000 and operating procedures originally produced in 2015 and revised annually) covered the basics of operations for the individual machines – for example, turning the machines on and off – it did not capture the multitudes of tasks that the operator conducted as part of their normal routine of caring for the machinery and the system of machines. Initially, the project started as an intensive training period of two months, running from January to March 2020 to allow longer periods of time with the operator to understand the system process of the machinery. However, it quickly became clear that capturing the rich, detailed knowledge and tacit skills of the operator, built up over many years of experience working with the machines, would require considerably more investment of time, so I developed a plan for a more carefully considered knowledge capture project.

As the line-manager responsible for the operation of our heritage machinery, I designed the knowledge capture process detailed in this article with our retiring operator. Due to unavoidable constraints, we had 17 working days to complete the knowledge transfer process, working with the operator to observe and interrogate while recording the operational process of the individual machines and the system. This was then further cut short to 14 working days due to the pandemic. As part of the process, I was also able to undertake hands-on training alongside the interrogation process, an autoethnography method known as participant observation (Ehn, 2011).

I had experience operating the machines to a basic level but also have a broader background in mechanical engineering, therefore the work was structured to maximise on the short timeframe. As she was close to retirement, the operator was keen to share her knowledge to help preserve the skill of operation for future training. It should be noted also that the process was collaborative and had to be approached sensitively to encourage the open flow of information. Prior to starting the process, I had already identified that there were some discrepancies between the documentation we held and the operator’s lived experience of operating the machinery. As we began, we acknowledged that there would be further differences between the written information and what the operator did in practice and, provided the differences were not causing unreasonable risk, it was important to understand the reasoning behind why these differences arose.

Aim

https://dx.doi.org/10.15180/211602/003The aim of this process was to attempt to capture knowledge on the operation and troubleshooting of the individual machines, as well as the relationship between the machines as part of the manufacturing process. The information captured would then be reviewed by a group of Science Museum Group staff responsible for the conservation, maintenance and health and safety of the machinery, to be included in updated documentation (where documents already existed) and to form the basis of a set of additional resources, including videos, to aid with future operations training.

Existing information search

https://dx.doi.org/10.15180/211602/005The first stage of the process is to conduct a search of existing information held in documents and other resources. These documents can include modern operation and maintenance manuals (including older versions where available), risk assessments and procedural notes, as well as historic documentation where held. The information within these documents forms the baseline to which regular operating practices can be compared. The information search itself may draw up inconsistencies within existing documents (information may be included on some documents but not others) and gaps in knowledge (where no information exists). Should substantial gaps be found, there is an opportunity at this point to gather information from other sources, for example from other heritage organisations who operate similar machinery. It may also be beneficial to draw up a map of documents to assess if any machines are missing any documentation and to outline what documents are available from which sources.

In our case, a selection of modern operation and maintenance (O&M) documents (produced in 2002) were provided by the maintenance team, along with a handful of educational videos (Hopper and Scutchner, 1997) about the machines that were produced by the Northern Consortium of Textiles Museums between 1995 and 1997. In addition to this, the Learning team had a set of standard operating procedures and risk assessments for specific tasks, as well as Victorian magazines that had been left behind by former staff, and handwritten notes and notebooks filled with data that had been kept by operators and had not been stored digitally. A set of recently created O&M manuals had been started as a joint venture by the departments responsible for working machinery but these had not been in production for long prior to this knowledge capture process beginning. Historic manuals for the machinery were also available from the Museum’s collection through the collections team. This initial information search also highlighted a significant assumption that, despite the teams having very strong communication, each department would rely on someone else having the information for a certain process (and thus would not write it down) when that was not necessarily true.

Once all the relevant documents and resources have been gathered, they should be compared against each other to begin pulling out topics for interrogation during the next stage, where the normal operation will be recorded. It is at this point that it will begin to become clear which topics are well covered and which have little to no information on them. A topic list should then be created to be used to structure the next stage of the process, detailing the basic operational procedures for each machine falling under the topics highlighted from the information search.

The topic list also provides the opportunity to examine the machinery operations through a different lens, considering areas such as accessibility. Within the field of heritage machinery, many cultural institutions have conservation policies that do not allow considerable adaptation of the machinery. For example, the Science Museum Group Conservation Policy states that any interventions should preserve the integrity of the object and are assessed on a case-by-case basis at regular intervals for operational objects (Science Museum Group, 2018). This can limit the accessibility of the machinery for the operators, as historic machines were built within the constraints of normalisation of the body, so can be inoperable in a safe manner for people of different heights, strength, reaches and body shapes, and for people with physical or sensory impairments. It is worth noting that this is also true of modern machinery and personal protective equipment (Ghani, 2017), and many facets of everyday life (Criado Perez, 2019). The topic list provides a vital opportunity to capture information like this to consider if further adaptations or new approaches and procedures to heritage machinery operations can be implemented within Collection and Conservation guidelines to align with modern health and safety practices. There can be conflict between these two aspects of machinery operating, as noted by Pye (2016) stating that ‘Preparing a working museum object for operation may run counter to the conservation concepts of retaining original material and of minimum intervention in terms of treatment’. Where this is the case, the topic list can allow the conductors and stakeholders in the process to find a suitable solution that brings compromise with non- or low-invasive safety mitigations that align with conservation guidelines while maintaining the operation of the object for the benefit for the visitor experience (Pye, 2016).

Over the breadth of documents collated, there were very few references to the system as a whole – i.e. how the machines work together to produce cloth. Practical process information such as how long it takes to use a bale of cotton, and how often machines require doffing based on the frequency of their use, was missing from written texts and could only be given best guesses by the operator based on their experience. We realised then that we had very little empirical information on the process, even though it would be obtained relatively easily by consciously noting when an event occurred and measuring it over a year to calculate frequency.

Creation of the topic list is an iterative process, and it may be that more topics emerge during the operation recording stage. Once it has been finalised to a point, it can either be used to consider the topics in their entirety or in a targeted manner, only covering specific points. Time can then be allocated to the project as appropriate.

For our approach, we conducted a full investigation looking at all the topics listed as we had acknowledged early on that we needed to establish the reasoning behind any changes to the normal operation of the machinery – whether that be for safety, conservation or efficiency. It was also an opportunity to capture any deviation in normal operation practices from the full written procedures, and to encourage an open iterative approach to this process to help address any gaps that were yet to appear.

Operation recording and interrogation

https://dx.doi.org/10.15180/211602/006The second stage of the process involves the first-hand recording of the regular operation of the machinery and management of the system of machines. This is to begin to capture any information that has been omitted from the existing documentation and to begin to interrogate any processes used. It should be structured following the topic list produced in stage one and should have sufficient time allocated to it to record any seasonal or weather-dependant changes where appropriate as historic machinery can be highly sensitive to temperature and humidity changes. If new topics emerge during recording, ensure they are reflected back into the topic list as top-level information as the planning of this process can be used to replicate the method in the future.

When structuring previous ‘intensive training periods’ for learning new machinery from scratch (or with new trainees), a minimum of around six months of training had been allocated to allow for seasonal changes in machinery operations and to witness a wide range of troubleshooting occurrences. This intensive training would happen for a couple of hours each day, allowing the information to be learnt and tested often. In this case, only 14 working days were available with the experienced operator due to the pandemic, so time had to be carefully planned and structured in advance.

During operation recording, it is important to be aware that any notes made could be used to expand on information in manuals and risk assessments, but also that they could become a useful training resource to help teach specific skills to trainees, the importance of which was discussed in the Museums Association Sharing Knowledge Toolkit (Museums Association, 2011). A variety of methods should be used to capture information, including video, sketches and labelled diagrams. This is to help contextualise the connections between various parts of the machines but also to capture how the operator interacts with said machines. For example, if a particular stance is required for manual handling constraints a narrated video would help illustrate how the operator uses their body weight to move with the rhythm of the machine and how much force is required in any given direction. Where possible, the operator should narrate the process while being filmed, and should be encouraged to include their own sensorial measures and kinaesthetic feedback from the machine to help verbalise some of the decisions they make while operating, as ‘thinking aloud accounts’ (Seiler, et al, 2021). Here it is also useful to consider the normalisation of the body and note any machine constraints that may impede accessibility for operators; for example, where operators have differing levels of strength, mobility and height. Videos including these ‘thinking aloud accounts’ can be filmed easily during the process using simple equipment such as a smartphone. This allows for a more fluid and spontaneous capture of information, as some information will naturally be shared conversationally in the collaborative process.

Textile machinery requires a process called piecing – the joining of ends of cotton (at any stage of the process prior to finished cloth), whether that is by knotting or twisting two threads together, or by thinning and overlapping them. Piecing methods used on each machine are different and vary on where the cotton breaks. It is particularly difficult to describe in written text or photos, so it was an area that needed to be captured during the operation recording. To do this we used narrated videos that explained each step in the process. Post recording, we tested these videos by using them as a how-to guide to see if they contained all the information a trainee would need to piece up a machine. If a trainee had specific questions after following the video or a part was highlighted as being unclear, these were considered in more depth and the video was re-recorded to include additional scaffolding as necessary.

Information gathered during this stage should be interrogated thoroughly to provide an understanding on the reasoning behind variations in operating procedures and reflect on their validity. This should be done in an open and honest manner, as variations may reflect good or poor practices. Should a dangerous practice be demonstrated, it should be stopped and addressed immediately. Operating methods should be interrogated in relation to two broad themes: their conformity with modern health and safety (for the protection of the operator) and conservation practices (for the protection of the machine), and specific process details regarding exactly what is being done and why. The broader scope of the latter theme of questioning helps identify further gaps in knowledge around specialist (or adapted) tools used, former factory influenced processes, machine faults and empirical data gathered.

A list of questions was developed to assist with interrogating the process (see List of questions used to interrogate a machine task). Much of the operational knowledge with the machinery was developed to replicate that of the original factory setting or had been created by staff who were former factory workers and trainers, thus there were procedures that were done with the speed of a factory in mind and not modern health and safety or collections care. In some cases, a novel operating technique was developed by the technician to serve as a workaround for a longstanding fault on the machine.

Some known physical constraints were also captured, where a machine’s configuration may hinder an operator from operating the machine in the intended way; for example, the location of the starting handle on the Intermediate Speedframe is hard to use for operators under 5’5” in height, so a change in procedure was discussed to allow for operation without altering the machine itself.

List of questions used to interrogate a machine task

- What is being done?

- Why is it being done that way?

- What would happen if that task was not done?

- Are there any different ways to do it to make it safer for the operator?

- Are there any different ways to do it to improve collections care?

- Are there aspects of this task that depend on the operator’s physicality?

- How long should this process take?

- How often does it need to be done?

- How does this machine connect to the next one in the system?

- What specialist/adapted tools do you need to do this task?

- Where do you keep the tools for this process?

- Is there anything on this machine that does not work correctly?

- Can we gather any empirical data from this process?

- What other ancillary materials are used in this process?

- Are there any marks drawn on to the machine? What do they represent?

- Are there any manual handling considerations for this task?

Technicians who worked with the machines adapted tools to help with specific tasks, thus it was important to identify what the tools were, where they were kept and if there were any ancillary materials used with the machines (particularly regarding troubleshooting). These adapted tools were often unmarked pieces of wood or bent metal tools, which to the untrained eye could be mistaken for waste. The machines had also been marked with various lines and arrows (often in chalk) to signify specific stopping and starting positions, as well as which way to turn belts for barring.

The gathering of empirical data should be encouraged during this stage to help rationalise, communicate and capture parts of the process that long-serving technicians may only know by ‘gut feeling’. Where possible this should also include capturing the vernacular used by the operator to allow further detail to be recorded about the process and any potential kinaesthetic attributes or sensorial measures of the procedures. These could be explored using the nine definitions of haptic exploratory procedures: contours, weight, proportion, temperature, texture, density, thickness, vibration, and breeze (Lederman and Klatzky, 1987; Akner-Koler and Rajbar, 2016, cited in Seiler, et al, 2021). For example, where the operator would say ‘nip it tight’ in relation to a wing nut, ‘move with the sley’ in relation to a manual handling technique used with the heavy sley of a Jacquard loom, and ‘pick the eyebrows off’ in relation to removing waste cotton from a top felt clearer on the roving frame.

The operator in this case study had enough experience of working with sliver (a stage of the cotton fabric manufacturing process, where the cotton resembles an untwisted rope), that she was able to assess the weight of the sliver by feel instead of weighing out the samples on a scale. Thankfully there was also some raw data of sliver weights and tolerances for the machinery so this could be easily duplicated.

It was in this line of questioning that we were able to gather most of our information about the machinery process as a system, such as how long a cotton bale would last and how long material can be held for in a particular state before it begins to degrade – a piece of information we unknowingly went on to test during the pandemic.

Throughout the recording and interrogation process there is opportunity to reflect upon the regular operating practices with the operator to begin a list of recommendations of changes to these processes where they could be improved upon. These recommendations then form the initial part of the next stage, where the information is deciphered to a greater degree.

Comparison and discussion of findings

https://dx.doi.org/10.15180/211602/007The results of the operation recording stage should be compared to the existing information and documentation found in stage one of the process to outline any discrepancies between them. The third stage of the process looks to find solutions to any issues raised and ensure all practices going forward are held to the highest standards. Once a list of discrepancies has been compiled, it should then be discussed with relevant stakeholders and suitably experienced persons to agree a way forward. Where necessary, external consultants can be approached to advise. All recommendations to changes in processes should be captured in a way that includes the justification for any changes. This will also aid in training and allow operators to fully understand any changes made.

The stakeholders for this case were the internal Museum departments involved in caring for the working machinery in the Textiles Gallery, the maintenance team who maintain the machinery, the learning team who operate the machinery, and the conservation and collections care team, all of whom hold specialist knowledge surrounding heritage machinery. The Museum is fortunate to have an internal health and safety department to consult with, who were able to give advice on broader topics such as manual handling.

One change that was introduced following consultation was to only piece up ends on the carding engine while it was stationary. It had previously been permissible to piece up while it was running as this was how it was done in the factory for speed of production. However, it is an intricate process that has many finger cut, trap and crush hazards where a great level of concentration is required due to the speed of the process. Initially we discussed bringing in additional mitigations including cut-resistant work gloves, but this would not eliminate the hazard. Upon further discussion with the maintenance team, a new piecing method was proposed, allowing the cotton to be pieced while the machine was static therefore eliminating the hazard. The reasoning for the change was written into the risk assessment for the machine operation.

After discussions with stakeholders, a list of recommendations and actions should be put together outlining the next steps.

Production of resources

https://dx.doi.org/10.15180/211602/008Utilising the map of documents created in the initial stages, assess where any new resources created should fit and which documents require updating based on the recommendations. Resources created or updated may include training or instructional videos as well as operational manuals, procedural documents and risk assessments. As they can be used to bolster training new technicians, any resources created should be made with ease of use in mind, ensuring they are high quality and provide the information needed with enough accuracy and in simple enough terms that they could be used by a non-specialist trainee. All documentation can be re-circulated to stakeholders as necessary and once finalised should have an appropriate review date added to them.

A set of new instructional videos on piecing were created to serve as a training aid for new trainees as well as a prompt for experienced operators for procedures that are done less frequently. On the carding engine these videos encompassed the new methods agreed as part of the stakeholder consultation and showed aspects of the procedures that would have been difficult to convey in a written form. The new procedures were reflected in the risk assessment, which is reviewed yearly, and a reference to the training videos can be included in the new manual that is in production.

This stage in the process allows for a reflective review not only to plug the knowledge gaps of any old documents but also to foster best practice in making any resources as well-rounded, simple to follow and accessible as possible to aid future training.

Limitations

https://dx.doi.org/10.15180/211602/009It is acknowledged that the approach knowledge capture outlined in this case study would not have been possible without access to a highly experienced operator who had considerable length of service operating these specific machines and the process. Heritage machinery is often anthropomorphised by the people who work closely with it, for the main reason that no two machines behave the same way; behaviours change from machine to machine, with the weather and seasons, and seemingly misbehave of their own volition. As such, having access to an operator who has worked extensively with the machines in question allows you an opportunity to capture additional troubleshooting information that an experienced operator from a different field, or an external consultant, may not bring to the process. Equally, there is benefit to the interrogator in the recording stage having experience of machine processes and ideally a good understanding on how to communicate nuanced concepts using a ‘science capital’ approach, one where everyday examples are used to allow a broader understanding of specific information (Science Museum Group, 2021).

As the process of knowledge capture is somewhat iterative in its early stages, it is advised that as much time as possible is given to the process. In this case study, the time with the experienced operator was cut short by the Covid-19 pandemic, which meant that some additional bits of information were discovered at the stakeholder review stage but weren’t able to be disseminated with the operator. It is also worth noting that there will inevitably be some information that is discovered after the process has finished, so any documents created should be considered as dynamic documents. The list of questions and method detailed in this article go some way to help discover what is unknown or unwritten about a machine’s operation. However, the age of the machines, the vast number of operators and technicians that have worked with them in their history and the iterative operational processes used with them over the years mean that new information will still be uncovered post this knowledge capture project coming to an end.

Tacit skills prove some of the hardest information to capture in this process and though the methods described here encourage use of a variety of medias to capture these, the importance of time spent with an operator acclimatising to the sights, sounds and kinaesthetic inputs of the machinery should not be understated. As mentioned in this case study, it should also be acknowledged that the experience of tacit skills is not standardised from one person to another, and in particular, working with heritage machinery relies heavily on physical and sensory inputs and outputs based on the expectation of the normalisation of the body of the operator from when the machine was originally designed and in use. In this way, many historic machines are not accessible by a large cross-section of people in their original form. Where collection and conservation policies allow, heritage machinery and the operational procedures for them should be adapted in appropriate ways to not only consider the basic health and safety of the operators as a group but also that of the individual operator and their own access needs.

Where tacit skills can be communicated there may be some future training opportunities to look towards capturing the analogue or human interaction side of some of these specific skills, where digital analysis already exists in industry. For example, physical or haptic models allowing kinaesthetic learning (Minogue and Jones, 2006) are already common in medicine (D’Abbraccio, et al, 2019) and physics (Neri, et al, 2018), or sound recording for fault detection, an engineering practice using automated feedback systems (Yanjin and Hardt, 2017). In these cases, technology designed to increase automation in industry could be retro-engineered to teach human-detection skills to preserve heritage operational knowledge as opposed to computer-detection skills, where automation is the desired outcome. Additionally, information capture techniques from other fields of work may be applicable to heritage machinery operations; for example, using choreography notation where the motion and rhythm of a human-machine interaction needs to be captured. However, there is still no one method of information recording that will encompass the range of sensorial and physical interactions required for heritage machine operations. As such, where possible, the information gathered should be used to continue heritage skills training and should bolster person-to-person training to ensure it meets modern standards, ideally using a structured apprenticeship-type model that considers the sensory nature of the human-machine relationship.

In contrast to the publicly-funded cultural sector where knowledge loss remains a high-risk issue, many of the concerns raised above can be overcome in the private heritage industry sector where production is still in demand for artisan-made items manufactured using heritage methods, especially where funding and grants can be applied to invest in modern apprenticeship schemes. This has successfully worked to save companies such as Sheffield scissor manufacturer Ernest Wright, as an artisanal price can be charged, thus protecting wages, allowing for job progression based on skill and increasing length of service. A compromise may be met where cultural institutions are able to adapt and gain investment through heritage funding sources to become producers of craft-led items and develop modern, structured apprenticeship schemes – unlike the vague, unstructured apprenticeships of the past and often associated with traditional crafts (Staubermann, 2010; Kneebone, 2020) – while still providing heritage interpretation to the general public. This model can be seen at Knockando Wool Mill (National Lottery Heritage Fund, 2009), Whitchurch Silk Mill (The Weave Shed, 2019) and New Lanark Industrial Community (Ross, 2013).

Without access to an experienced operator as a trainer, or without a working machine, risk of knowledge loss still exists. The methods outlined here do no eliminate the risk of knowledge loss, they merely reduce it so it becomes manageable. More work is needed across the heritage sector to increase training and advocate for paid operational roles to tackle the sustainability and future of heritage machinery operations.

Conclusion

https://dx.doi.org/10.15180/211602/010The method used in this case study successfully captured a large amount of information on the operation, troubleshooting and system process of the heritage textile machinery at the Science and Industry Museum. The information gathered, and the resources produced during the process, went some way to reducing the risk of knowledge loss of these specialist machines, as well as ensuring that any procedures used reflected both modern health and safety and conservation and collections care guidelines. In addition, the cross-media resources produced will be used to support a robust training pathway to enable a more complete machinery operations training package, as well as providing a solid basis for encouraging the production of accessible documentation in the future. With further investment in staffing this will, in turn, improve the outlook for preserving heritage knowledge and skills and will directly impact the visitor experience at the Museum by allowing a more sustainable opportunity for an immersive STEM experience.

Acknowledgements

I would like to express my great appreciation to Carole Hurd for allowing me to work with her in capturing her expansive knowledge and skill in working with the textile machinery at the Science and Industry Museum. I would also like to thank Stephen Hoyle and Hannah O’Toole and their colleagues for their contribution in providing documentation for the information search, for their advice regarding health and safety and for their assistance in producing new resources. Finally, I am particularly grateful for the encouragement given to me by Sarah Baines on the production of this article.